FAT-D-SFW Pneumatic Stainless Steel Wafer PTFE Butterfly Valve

FAT-D-SFW Pneumatic Stainless Steel Wafer PTFE Butterfly Valve

The Pneumatic Stainless Steel Wafer PTFE Butterfly Valve features a stainless-steel body and PTFE-lined seat for strong corrosion resistance, providing tight sealing and reliable pneumatic control in chemical and marine systems, proven by ISO 5211 and API 598 test standards.

Technical Specifications

| Size Range | DN50–DN300 (2″–12″) |

| Working Pressure Range: | PN10 / PN16 (150 PSI) |

| Working Temperature Range: | -20°C to +180°C |

| Body Material: | CF8 / CF8M (Stainless Steel 304 / 316) |

| Connection Type: | Wafer Type |

| Applicable Medium: | Corrosive fluids, acids, alkalis, solvents, seawater |

| Actuator Type: | Pneumatic actuator (Double Acting / Spring Return) |

| Voltage Options | 24V DC, 110V AC, 220V AC |

| Design Standard | ISO 5211, MSS SP-67 |

| Testing Standard | API 598, EN 12266-1 |

| Fire-Safe Design | Optional per API 607 |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

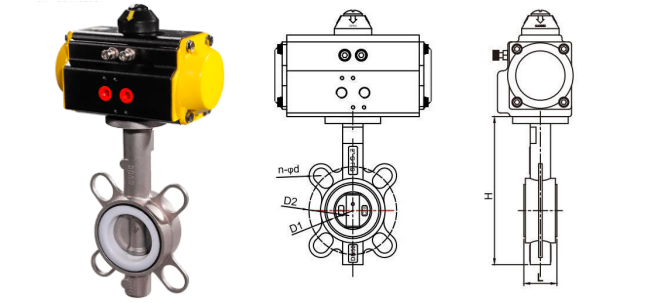

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Performance & Reliability

• Pneumatic stainless steel butterfly valve ensures precise flow control with high-torque actuation.

• PTFE-lined wafer design provides tight sealing and strong corrosion resistance.

• Stainless steel valve body resists rust, oxidation, and wear in harsh conditions.

• Optimized flow path reduces pressure loss and improves flow efficiency.

2. Chemical & Environmental Resistance

• PTFE-coated disc and seat isolate media for acids, alkalis, and corrosive fluids.

• Industrial wafer butterfly valve withstands saltwater, vapor, and chemical exposure.

• Non-reactive materials fit pharmaceutical, food, and ultra-pure water systems.

• Eco-sealing prevents leaks and emissions for safe operation.

3. Automation & Control Flexibility

• Air-actuated wafer butterfly valve supports double-acting or spring-return control.

• Compatible with solenoid valves, limit switches, and positioners.

• ISO 5211 interface allows easy actuator installation.

• Voltage options: 24V DC, 110V AC, 220V AC.

4. Installation & Maintenance Efficiency

• Compact wafer-type design saves space and installs easily between flanges.

• Lightweight pneumatic unit simplifies handling and setup.

• PTFE seat ensures low torque and long service life.

• Modular design allows quick inspection and part replacement.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What options are available for controlling a high-performance pneumatic wafer butterfly valve in automated systems?

• Pneumatic stainless steel butterfly valve supports double-acting and spring-return actuators for fast and precise automation.

• Wafer body design fits easily between flanges for quick retrofit in automated pipelines.

• ISO 5211 mounting allows seamless integration with smart control systems.

• Voltage options 24 V DC, 110 V AC, 220 V AC suit diverse automation setups.

2. How does the PTFE-lined wafer design deliver long-term reliability for chemical-processing applications?

• PTFE-lined wafer butterfly valve resists acids, alkalis, and solvents for corrosion-free operation.

• Stainless steel valve body provides strength and durability under harsh conditions.

• Wafer configuration minimizes leakage and ensures stable flow control.

• Low-friction PTFE seat reduces torque demand and extends actuator life.

3. What should be considered when installing a wafer-type butterfly valve in a corrosive environment?

• Verify flange dimensions and bolt patterns for proper alignment and sealing.

• Ensure adequate air pressure and actuator sizing for the industrial wafer butterfly valve.

• Check PTFE seal seating during installation to prevent early leakage.

• Choose modular construction to replace discs and seats without removing the pipeline.

4. Can a PTFE-lined butterfly valve be used in fire-safe or high-temperature applications?

• Standard PTFE-lined butterfly valve handles temperatures up to 180 °C with consistent sealing.

• Fire-safe variants use reinforced seats or metal carriers for thermal protection.

• Actuator and mounting interface must match ambient temperature limits.

• Certified designs meet API 607 and ensure safe performance under heat exposure.