FAT-D-SH Pneumatic Stainless Steel Hard-Seated Butterfly Valve

FAT-D-SH Pneumatic Stainless Steel Hard-Seated Butterfly Valve

The Pneumatic Stainless Steel Hard-Seated Butterfly Valve uses a metal seat for tight sealing in high temperature and pressure, ensuring long life, low maintenance, and API 609 and API 607 fire-safe certified reliability.

Technical Specifications

| Size Range | DN50–DN600 (2″–24″) |

| Working Pressure Range: | PN10–PN40 / Class 150–300 |

| Working Temperature Range: | -29°C to +450°C |

| Body Material: | Stainless Steel |

| Connection Type: | Wafer or Flanged (ASME, DIN, JIS) |

| Applicable Medium: | Steam, Gas, Oil, Corrosive Fluids, High-Temperature Media |

| Actuator Type: | Double-Acting or Spring-Return Pneumatic Actuator |

| Voltage Options | 24V DC, 110V AC, 220V AC |

| Design Standard | API 609 / ISO 5752 |

| Testing Standard | API 598 / EN 12266-1 |

| Fire-Safe Design | Yes (API 607) |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

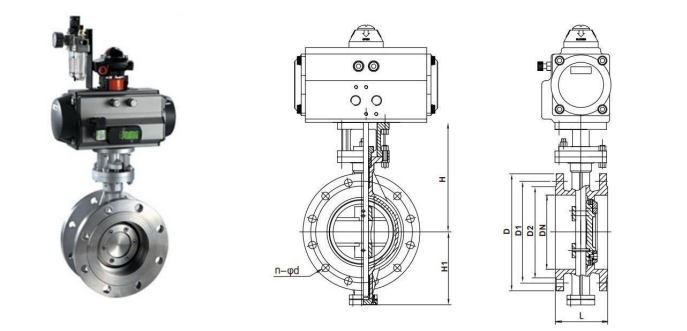

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Performance & Durability

• Pneumatic Stainless Steel Hard-Seated Butterfly Valve uses a metal-to-metal seat for tight sealing in high-pressure, high-temperature systems.

• Stainless-steel valve body resists corrosion and abrasion for long service life.

• Precision pneumatic actuator valve ensures stable torque and accurate flow control.

• Tested to API 598 and API 607 fire-safe standards for reliable shutoff performance.

2. Efficiency & Cost Optimization

• Industrial butterfly valve requires low torque, reducing air consumption and energy use.

• Streamlined disc design delivers high flow efficiency and low pressure loss.

• Durable sealing components extend maintenance intervals, lowering total cost.

• Modular actuated valve assembly enables quick installation and replacement.

3. Safety & Reliability

• Hard-seated butterfly control valve features fire-safe and anti-blowout stem design for hazardous media.

• Double-offset disc minimizes seat wear, maintaining sealing integrity over time.

• Spring-return pneumatic actuator offers fail-safe shutoff on power or air loss.

• Certified by CE, ISO 9001, SIL, ensuring safety and quality compliance.

4. Application Versatility

• Suitable for chemical, oil & gas, steam, and high-temperature applications.

• Available in wafer or flanged connection per ASME, DIN, and JIS standards.

• Stainless pneumatic valve operates reliably across wide temperature and pressure ranges.

• Compatible with solenoid valves and position feedback units for automated control.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What maintenance is required for a Pneumatic Stainless Steel Hard-Seated Butterfly Valve to ensure long-term reliability?

• Inspect the metal-seated butterfly valve regularly to prevent wear from high-pressure cycles.

• Clean internal surfaces and lubricate the pneumatic actuator valve for stable torque and smooth operation.

• Check actuator calibration and air pressure to ensure complete valve stroke.

• Verify fire-safe and anti-blowout components for safe use in steam or hazardous media.

2. How does a hard-seated pneumatic valve perform under high temperature and pressure compared to soft-seated designs?

• The stainless steel butterfly valve maintains tight sealing above 400°C without seat deformation.

• Metal-to-metal sealing resists abrasive flow, suitable for steam, gas, and slurry applications.

• Certified to API 609 and API 598 for reliable high-pressure performance.

• The pneumatic control valve actuator ensures consistent shutoff under demanding conditions.

3. What are the key advantages of a Pneumatic Metal-Seated Butterfly Valve for industrial automation?

• The pneumatic stainless steel valve delivers fast response and accurate flow control.

• Hard-seat design minimizes maintenance and extends service life in continuous operation.

• High sealing pressure prevents leakage, improving energy efficiency.

• Supports integration with smart actuator systems for automated monitoring and control.

4. How to select the correct actuator configuration for a pneumatic hard-seated butterfly valve?

• Choose double-acting or spring-return actuators based on safety and process needs.

• Match actuator torque to pressure and media for stable operation.

• Ensure mounting follows ISO 5211 for easy integration with accessories.

• Use actuators with SIL or ATEX certification for explosive or high-risk areas.