FAT-Q-B Pneumatic Thin Type Wafer Ball Valves

FAT-Q-B Pneumatic Thin Type Wafer Ball Valves

The Pneumatic Thin Type Wafer Ball Valve features a compact stainless-steel wafer body for space-saving installation and full-bore flow, providing fast pneumatic actuation with precise control, leak-free sealing, and verified durability through API 598 and ISO 5211

Technical Specifications

| Size Range | DN15–DN200 (1/2″–8″) |

| Working Pressure Range: | PN10–PN40 (up to 580 psi) |

| Working Temperature Range: | –20 °C to +180 °C |

| Body Material: | Stainless Steel (CF8 / CF8M) |

| Connection Type: | Wafer Type (fits between PN10/PN16/ANSI150 flanges) |

| Applicable Medium: | Water, Air, Oil, Steam, Corrosive Fluids |

| Actuator Type: | Double-Acting or Spring-Return Pneumatic Actuator |

| Voltage Options | 24 V DC / 110 V AC / 220 V AC |

| Design Standard | ISO 5211, ASME B16.34 |

| Testing Standard | API 598, EN 12266-1 |

| Fire-Safe Design | Optional per API 607 / ISO 10497 |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

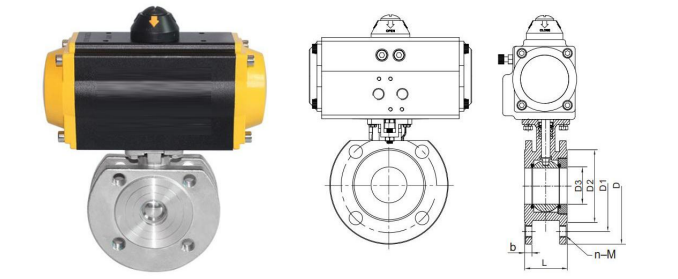

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Structural & Material Advantages

• Pneumatic Thin Type Wafer Ball Valve with compact wafer body ensures full-bore flow and minimal space use.

• Stainless steel pneumatic valve (CF8/CF8M) provides strong corrosion resistance and durability.

• Lightweight air-operated wafer ball valve design reduces system load and installation cost.

• PTFE seat and reinforced stem guarantee tight sealing and long service life.

2. Automation & Control Performance

• Pneumatic actuated ball valve delivers fast, stable on/off control for automated pipelines.

• Double-acting or spring-return actuator options for flexible operation.

• Supports solenoid valves, limit switches, and position indicators for integrated automation.

• ISO 5211 mounting pad enables direct actuator installation and easy maintenance.

3. Application & Reliability Benefits

• Suitable for compressed air, water, oil, steam, and corrosive fluids.

• Automated wafer ball valve tested to API 598 ensures zero leakage.

• Fire-safe design option enhances safety in chemical and process industries.

• High-cycle performance with stable torque reduces maintenance needs.

4. Installation & Maintenance Efficiency

• Thin wafer pneumatic valve fits PN10/PN16/ANSI150 flanges for quick installation.

• Compact, lightweight structure enables single-person handling.

• Modular actuator allows replacement without removing valve body.

• Replaceable seat and seals lower long-term maintenance costs.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What are the key installation requirements for a Pneumatic Thin Type Wafer Ball Valve in automated systems?

• Center the wafer-style pneumatic ball valve precisely between flanges and tighten bolts evenly to prevent leaks.

• Keep the pneumatic actuator upright and ensure proper alignment for stable rotation and sealing.

• Use clean, filtered air to maintain consistent torque and extend actuator life.

• Flush pipelines before setup to remove debris that can damage seats or the stainless-steel ball surface.

2. How to choose the right air-operated wafer ball valve for high-cycle automation?

• Select a full-bore pneumatic wafer valve to minimize pressure drop and improve flow efficiency.

• Match body and seat materials—such as CF8M stainless steel and PTFE seals—to your medium and temperature range.

• Choose double-acting or spring-return actuators based on control accuracy and safety needs.

• Prioritize lightweight thin-type wafer valves for compact installations and quick system response.

3. How to maintain a compact pneumatic wafer valve for long-term reliability?

• Inspect actuator mounts and ISO 5211 interfaces regularly for wear or looseness.

• Ensure the air control system delivers dry, clean air to prevent corrosion or seal failure.

• Monitor torque and closing performance to detect early seat or stem wear.

• Replace PTFE seats and O-rings periodically in high-cycle environments to avoid downtime.

4. In what applications does a thin pneumatic wafer ball valve perform best?

• Ideal for space-limited pipelines, water treatment systems, HVAC lines, and chemical dosing units.

• Provides quick on/off flow control for air, oil, steam, and mild corrosive fluids.

• Suitable for industrial automation systems requiring precise flow regulation.

• A reliable alternative to flanged valves where lightweight, easy installation is essential.