FAT-Q-PD Pneumatic Plastic 3-Way Double Union Ball Valve

FAT-Q-PD Pneumatic Plastic 3-Way Double Union Ball Valve

The Pneumatic Plastic 3-Way Double Union Ball Valve features a corrosion-resistant UPVC/CPVC body and 3-port design, ensuring precise flow control, leak-free operation, and long service life—validated by ISO 5211 mounting, PTFE seals rated to 16 bar, and 100,000 cycle durability tests.

Technical Specifications

| Size Range | DN15 – DN100 (1/2″ – 4″) |

| Working Pressure Range: | PN10 – PN16 (10–16 bar / 145–232 PSI) |

| Working Temperature Range: | 0°C – 60°C (UPVC), 0°C – 90°C (CPVC) |

| Body Material: | UPVC / CPVC / PVDF |

| Connection Type: | Double Union Socket or Threaded (BSPT/NPT) |

| Applicable Medium: | Water, Acid, Alkali, Saline Solution, Chemical Liquids |

| Actuator Type: | Pneumatic Rack & Pinion, Double Acting or Spring Return |

| Voltage Options | Air Supply 4–7 bar, Solenoid 24VDC / 110VAC / 220VAC |

| Design Standard | ISO 5211, DIN / ANSI / JIS |

| Testing Standard | EN 12266-1, ISO 9393 |

| Fire-Safe Design | Not Applicable |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

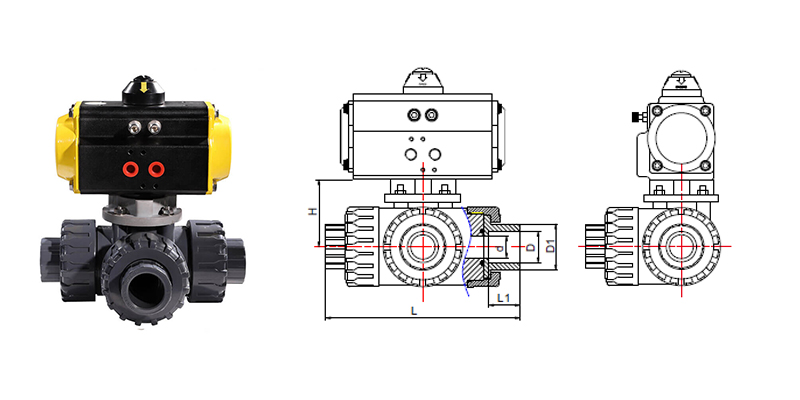

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Flow Control & Efficiency

• Pneumatic Plastic 3-Way Double Union Ball Valve provides accurate flow diversion or mixing in automated piping systems.

• Full-port design reduces pressure loss and improves fluid transfer efficiency.

• Pneumatic actuator delivers fast, repeatable switching for stable control.

• Compact, lightweight structure fits tight installation spaces.

2. Corrosion Resistance & Durability

• UPVC/CPVC pneumatic 3-way valve resists acids, alkalis, and saline solutions for long service life.

• PTFE seats and FPM/EPDM seals ensure reliable, leak-free performance.

• Non-metallic body eliminates rust and corrosion in chemical systems.

• Thermoplastic housing provides strength and UV stability for outdoor use.

3. Installation & Maintenance

• Double union ends allow quick removal and replacement without cutting pipes.

• ISO 5211 mounting pad supports direct actuator connection.

• Lightweight plastic construction simplifies handling and setup.

• Socket or threaded ends compatible with DIN, ANSI, and JIS standards.

4. Automation & Integration

• Works with double-acting or spring-return pneumatic actuators.

• Optional solenoid and limit switch enable remote control and signal feedback.

• Pneumatic 3-way valve integrates easily with PLC or SCADA systems.

• Low air consumption and high torque efficiency support energy-saving operation.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What makes the Pneumatic Plastic 3-Way Double Union Ball Valve ideal for automation systems?

• Air-actuated 3-way union valve combines three flow paths in one unit for efficient flow diversion or mixing.

• Compact, lightweight body ensures smooth operation in limited spaces.

• Corrosion-resistant thermoplastic structure suits chemical, water treatment, and industrial fluid systems.

• Pneumatic actuator provides fast, reliable switching for precise control.

2. How does the UPVC pneumatic 3-way ball valve perform in chemical applications?

• UPVC and CPVC materials resist acids, alkalis, and saline liquids effectively.

• PTFE seats and EPDM/FPM seals maintain long-term leak-free performance.

• Non-metallic body prevents rust and galvanic corrosion in aggressive media.

• Plastic true-union valve allows quick maintenance without cutting pipelines.

3. What should be considered when installing a pneumatic 3-way control valve?

• ISO 5211 mounting pad enables direct actuator installation.

• Match actuator torque with valve body strength to prevent deformation.

• Add solenoid valves or limit switches for automated feedback control.

• Correct air supply and logic ensure accurate switching between L-port and T-port.

4. Should I choose an L-port or T-port pneumatic plastic ball valve?

• L-port design diverts one inlet to two outlets or isolates flow paths.

• T-port design allows mixing or combining flows for multi-line systems.

• Pneumatic diverter valve with T-port handles complex circulation efficiently.

• Verify actuator position and flow direction to prevent dead-leg flow.