FAT-Q-P Pneumatic Plastic 2-Way Double Union Ball Valves

FAT-Q-P Pneumatic Plastic 2-Way Double Union Ball Valves

The Pneumatic Plastic 2-Way Double Union Ball Valve features a corrosion-resistant UPVC body and double-union design for fast installation and maintenance, providing reliable automated flow control in chemical and water systems; ISO 9393 and CE testing verify its sealing performance and durability.

Technical Specifications

| Size Range | DN15–DN100 (½″–4″) |

| Working Pressure Range: | PN10 / 150 PSI |

| Working Temperature Range: | 0°C–60°C (UPVC), up to 90°C (CPVC) |

| Body Material: | UPVC / CPVC / PP / PVDF |

| Connection Type: | Double Union Socket or Threaded (BSP/NPT) |

| Applicable Medium: | Water, Acid, Alkali, Salt Solution, Corrosive Chemicals |

| Actuator Type: | Pneumatic Rack and Pinion |

| Voltage Options | 24V DC / 110V AC / 220V AC |

| Design Standard | ISO 5211 / DIN / JIS / ANSI |

| Testing Standard | ISO 9393 / GB/T 13927 |

| Fire-Safe Design | Not Applicable (Thermoplastic body) |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

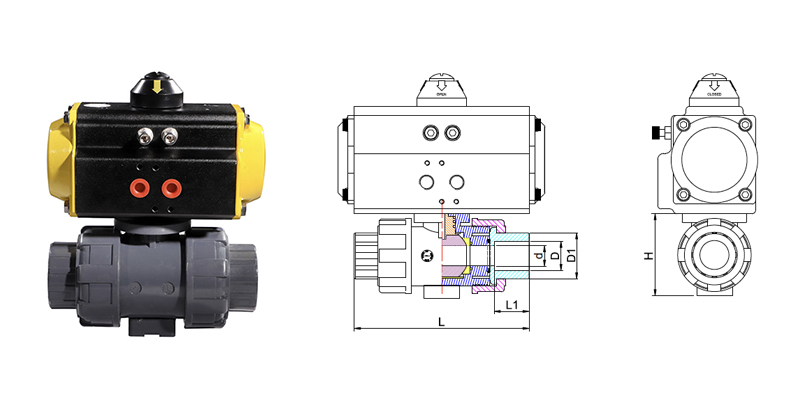

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Corrosion & Chemical Resistance

• Pneumatic Plastic 2-Way Double Union Ball Valve made from UPVC offers strong corrosion and chemical resistance in acid, alkali, and saline conditions.

• Air-operated plastic ball valve resists oxidation and contamination in corrosive fluid systems.

• Smooth flow path reduces residue buildup and maintains stable fluid control.

• PVC pneumatic actuator valve performs reliably in chemical, marine, and wastewater

2. Easy Installation & Maintenance

• Double union air control valve allows quick disassembly without cutting pipes.

• Lightweight thermoplastic body simplifies installation and reduces pipeline stress.

• ISO 5211 mounting pad supports direct pneumatic actuator connection.

• UPVC pneumatic valve fits threaded or socket connections in PVC, CPVC, and PP systems.

3. Efficient Pneumatic Control

• Rack-and-pinion pneumatic actuator ball valve provides fast, precise on/off control.

• Single-acting or double-acting options suit different automation systems.

• Delivers consistent torque with low air consumption.

• Supports solenoid valve and limit switch for remote or PLC control.

4. Durability & Compliance

• Pneumatic union ball valve tested per ISO 9393 and GB/T 13927 for pressure and leak performance.

• Certified with CE, RoHS, and ISO 9001 for global compliance.

• Non-metallic design prevents corrosion and wear in non-flammable media.

• IP65 actuator protection ensures reliable use in humid or outdoor environments.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1.What is the difference between a standard ball valve and the Pneumatic Plastic 2-Way Double Union Ball Valve for automated systems?

• The double-union design allows quick removal without cutting the pipeline.

• Pneumatic actuation enables fast, automatic control for remote operation.

• Plastic body provides superior corrosion resistance in aggressive media.

• Two-way configuration ensures reliable on/off isolation for clean flow control.

2.How do I select the right size and pressure rating for a pneumatic plastic union ball valve?

• Match valve size to pipeline diameter to prevent pressure loss.

• Ensure the system pressure stays within the valve’s rated range.

• Confirm air-supply and actuator pressure compatibility for reliable automation.

• Check material temperature limits to prevent deformation under high heat.

3.What are common maintenance issues with the pneumatic plastic double-union ball valve?

• Properly tighten unions to avoid leaks at connection points.

• Flush the system to remove debris that may block the ball cavity.

• Maintain clean air supply to prevent actuator delay or failure.

• Inspect for cracks or discoloration in UV-exposed or chemical environments.

4.Where does the pneumatic plastic 2-way double-union valve perform best, and when should alternatives be used?

• Ideal for chemical dosing, wastewater, and water-treatment systems.

• Suitable for automated pipelines requiring air-driven control.

• Not recommended for high-temperature or high-pressure applications.

• Use other valve types for multi-way flow or extreme shut-off conditions.