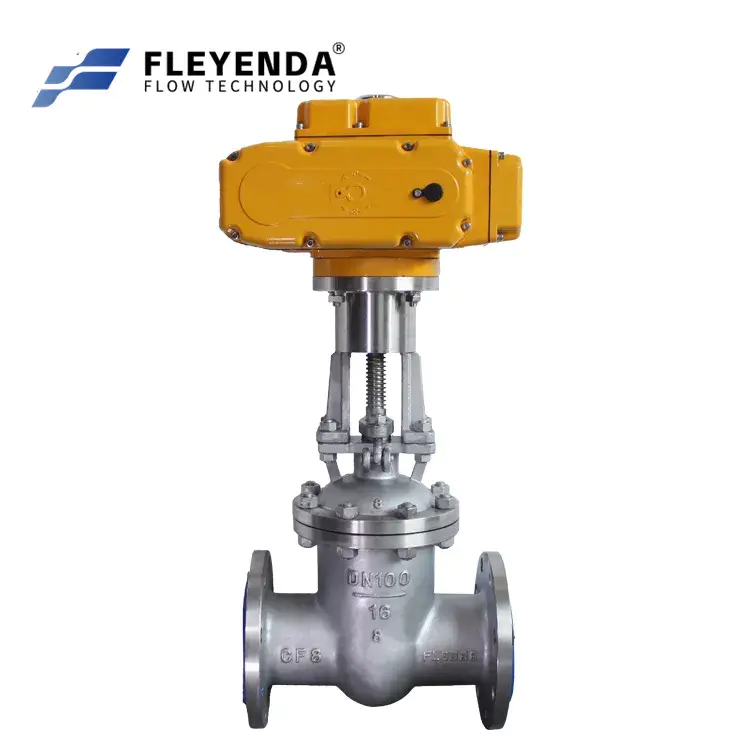

FLE-QT-FGV High-Temperature Electric Actuator Automatic Explosion-proof Gate Valve

FLE-QT-FGV High-Temperature Electric Actuator Automatic Explosion-proof Gate Valve

FLE-QT-FGV one-way electric straight-through gate valve is made of carbon steel, suitable for water, steam, oil, and other media, with a maximum operating temperature of 425°C.

Technical Specifications

| QH Series Mini Electric Explosion-proof Actuator | |

|

QH Mini Multi-turn Explosion-proof Actuator

|

Switch-type Actuator (Type A Control Circuit): The switch-type actuator only has a full-open and full-closed limiting position. After receiving appropriate instructions, the actuator will drive the valve to the full-open or full-closed position.

S2 short-time type operating mechanism is adopted. Continuous running time does not exceed 15 minutes. |

| Feedback-type Actuator (Type B Control Circuit): While driving valve, the actuator sends the valve position signal to the central control system during the whole process.Type B feedback resistance valve position signal.

S2 short-time type operating mechanism is adopted. Continuous running time does not exceed 15 minutes. |

|

| Regulating-type Actuator (Type C Control Circuit): A servo controller is installed inside actuator, receives the central control system’s instructions to drive the valve to the appropriate opening position according to the changes of controlled variables (flow, pressure, temperature and liquid level) in the pipeline.

S4 intermittent operating mechanism is adopted. Operating frequency per hour can reach 1200 times. Input instructions from the control system |

|

| Optional Type | ON-OFF and Modulating Type |

| Protection Grade | IP67 |

| Explosion-proof Grade | EXD IIB T4 |

| Power Supply | AC24V, AC110V, AC220V |

| Standard Time / Torque | 20S/50Nm |

| Rotation Angle Range | 0~360° Adjustable |

| Optional Control Circuit | A/B/C/D |

| Weight | 3.0Kg |

| Insulation Resistance | AC24V:100M2/250V; DC AC110V/AC220/AC380V:100M Q/500VDC |

| Pressure Resistant Grade | AC24V:500VAC 1 minute; AC110V/AC220V:1500VAC 1minute |

| Electrical Interface | 2-G1/2 explosion-proof end caps should be instaled with corresponding explosion-proof cable joints by users in time of use. |

| Environment Temperature | -20°~+60° |

| Optionallnstalation Function | Dehumidifying heater |

| Gate Valve Body | |

| Size Range | DN40-DN600 |

| Body Material | Stainless Steel |

| Seat Material | EPDM/PTFE |

| Connection Type | Flanged (GB/ANSI/JIS/DIN) |

| Working pressure | 10K-20K |

| Temperature Of Medium | 425℃ |

| Applications | Water, solvent, acid, natural gas, oxygen, hydrogen peroxide, methane, ethylene, etc. |

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Stable Performance & Reliable Operation

•Optimized flow path ensures low fluid resistance and stable pressure control

•Fast response and smooth opening/closing under frequent operation

•Reliable shut-off performance for water, gas, and chemical applications

2. Electric Actuator with Flexible Control

•QH Series mini explosion-proof electric actuator with compact design

•ON-OFF, modulating, and intelligent control options available

•Supports 4–20 mA, 1–5 V and other control signals

•Built-in over-torque, ESD, and fault protection for safe operation

3. High-Strength Materials & Corrosion Resistance

•Valve body made of stainless steel or cast steel (CF8, CF8M, WCB, etc.)

•EPDM / PTFE sealing materials with excellent chemical and aging resistance

•Suitable for high-pressure, high-temperature, and corrosive media

4. Easy Maintenance & Long Service Life

•Compact structure reduces wear and maintenance frequency

•Low torque operation extends actuator and valve lifespan

•Quick maintenance helps reduce downtime and operating costs

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1.What kinds of customized services can Fleyenda provide?

Private Labeling, Material Selection, dimensions customized, Actuator Options, etc. We also offer fittings and piping for optional.

Fleyenda is committed to providing you with a one-stop service.

2.How does Fleyenda Valve control the products quality?

We have the IPQC and QC process. We regularly do pressure testing, leakage testing, material analysis, and performance testing. Fleyanda Valve holds ISO 9001, CE, and other certifications.

Fleyedna focuses on upgrading production facilities, testing facilities and focuses on innovation to provide customers with high-quality products in the industry.

3. Can you help us to choose the right products?

Yes, We can help you choose the right valves for your needs. To do so, we would need some specific information from you.

-What is the application or industry which the valves will be used (e.g., oil and gas, water treatment, chemical processing)?

-What is the fluid or gas that will be flowing through the valves?

-What is the working pressure and temperature range for the valves?

And so on.

4.How long does it take you to prepare the goods?

We have a large number of products in stock and can be ready within 7 days. Customized products require 30 days of lead time.