QT-D-SH Motorized Stainless Steel Hard-Seated Butterfly Valve

QT-D-SH Motorized Stainless Steel Hard-Seated Butterfly Valve

The Motorized Stainless Steel Hard-Seated Butterfly Valve features a metal-to-metal seal for zero leakage under high pressure and temperature, providing corrosion resistance, precise flow control, and long service life—proven by 100,000-cycle testing and API 609, API 598, CE certification.

Technical Specifications

| Size Range | DN50–DN1200 (2″–48″) |

| Working Pressure Range: | PN10–PN40 / Class 150–300 |

| Working Temperature Range: | −20°C to +450°C |

| Body Material: | CF8 / CF8M |

| Connection Type: | Flanged |

| Applicable Medium: | Steam, hot air, oil, gas, chemical media, high-temperature water |

| Actuator Type: | Electric actuator |

| Voltage Options | AC220V, AC380V, DC24V |

| Design Standard | API 609 / EN 593 |

| Testing Standard | API 598 / ISO 5208 |

| Fire-Safe Design | Optional per API 607 |

| Certification | CE / ROHS / ISO / SIL / TUV /IP68 Waterproof |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

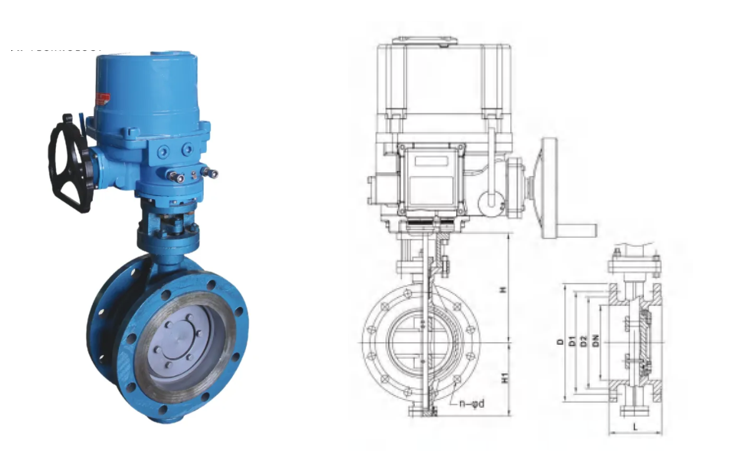

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Performance & Reliability

• Motorized stainless steel hard-seated butterfly valve ensures tight metal-to-metal sealing under high temperature and pressure.

• Stainless steel body and disc resist corrosion and abrasion in chemical, steam, and oil systems.

• Electric actuated valve provides precise torque and stable flow control.

• Automated butterfly valve design extends service life and reduces downtime.

2. Automation & Control Efficiency

• Electric butterfly valve supports PLC/DCS integration for precise remote control.

• Actuator control system offers accurate modulating or on-off operation.

• Manual override enhances safety during power loss.

• Motor-operated valve supports AC220V, AC380V, and DC24V for flexible automation.

3. Application Versatility

• Stainless steel motorized valve fits power, oil, gas, and chemical applications.

• Metal-seated butterfly valve withstands abrasive, high-pressure, and hot media.

• Flanged connection (ASME / EN) allows easy installation and global compatibility.

• Handles steam, gas, hot air, and liquids in demanding industrial systems.

4. Safety & Compliance Assurance

• Fire-safe design per API 607 ensures safety in high-risk conditions.

• Electric hard-seated valve tested to API 598 and ISO 5208 for zero leakage.

• Certified with CE, ISO9001, and RoHS for global compliance.

• Explosion-proof electric actuator provides safe operation in hazardous areas.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1.What operating conditions should I check before choosing a Motorized Stainless Steel Hard-Seated Butterfly Valve?

• Verify system pressure, temperature, and flow to ensure the electric hard-seated butterfly valve suits high-temperature service.

• Confirm the media type to match the stainless steel body and corrosion-resistant seat.

• Ensure the electric actuator valve power matches your automation setup.

• Check that the flange connection meets ASME or EN standards.

2. Why might a motorized metal-seated valve leak or fail to close completely?

• Solid particles may block full closure between disc and seat.

• Pipeline misalignment can deform the stainless steel butterfly valve body or disc.

• Worn or corroded sealing faces reduce tight shut-off in a metal-seated control valve.

• Incorrect actuator torque or limit switch calibration may leave the disc partially open.

3. How do I integrate a motor-operated butterfly valve into an automated control system?

• Align the actuator with the ISO 5211 interface for proper torque transfer.

• Connect control signals for modulating or on-off operation.

• Add feedback sensors to monitor the electric butterfly valve position via PLC or DCS.

• Choose actuator protection with IP65 or higher for harsh environments.

4.In which applications does a stainless steel motorized butterfly valve perform best?

• Suitable for high-pressure or high-temperature steam, oil, or gas systems.

• Ideal for abrasive or corrosive fluids in power, chemical, and refinery applications.

• Used in industrial automation for precise remote flow control.

• The hard-seat butterfly design maintains sealing where soft seats fail.