QT-D-CEW Motorized Cast Iron EPDM Butterfly Valve

QT-D-CEW Motorized Cast Iron EPDM Butterfly Valve

The Motorized Cast Iron EPDM Butterfly Valve combines a cast iron body, EPDM seat, and electric actuator for precise flow control, ensuring leak-free operation, corrosion resistance, and long service life, verified by PN16 pressure tests and CE, RoHS, ISO 9001 certifications.

Technical Specifications

| Size Range | DN50–DN600 (2″–24″) |

| Working Pressure Range: | PN10 / PN16 (150 PSI) |

| Working Temperature Range: | −10 °C to +120 °C |

| Body Material: | Cast Iron |

| Connection Type: | Wafer or Lug Type |

| Applicable Medium: | Water, Air, Neutral Liquids, Light Chemicals |

| Actuator Type: | Electric Quarter-Turn Actuator |

| Voltage Options | AC220V / AC110V / AC24V / DC24V |

| Design Standard | ISO 5211, EN 593 |

| Testing Standard | API 598, EN 12266-1 |

| Fire-Safe Design | Optional, API 607 |

| Certification | CE / ROHS / ISO / SIL / TUV /IP68 Waterproof |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

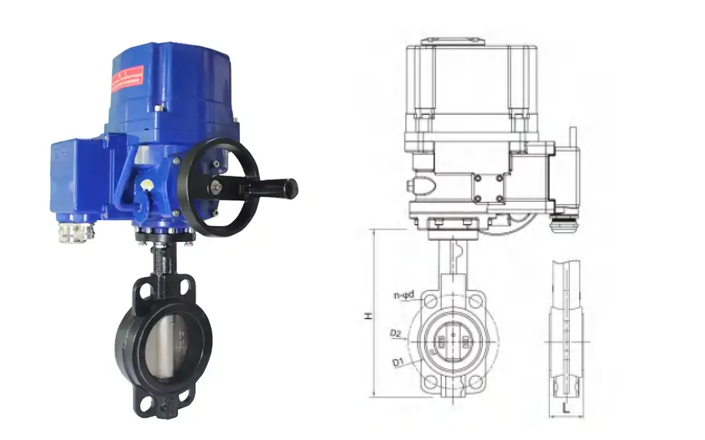

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Performance & Reliability

• The motorized cast iron EPDM butterfly valve offers precise flow control and stable torque for HVAC and water systems.

• The electric actuator valve ensures tight sealing with a durable EPDM liner, preventing leaks under pressure.

• The industrial butterfly valve body provides strong mechanical stability and corrosion resistance.

• Tested for leak-tight performance, minimizing maintenance and downtime.

2. Automation & Control Efficiency

• The electric actuated butterfly valve supports remote and modulating control for automated pipelines.

• Multi-voltage electric control valve design fits AC/DC systems easily.

• The ISO 5211 mounting pad enables fast actuator replacement and integration.

• The smart valve actuator includes manual override for emergency operation.

3. Installation & Maintenance Convenience

• The wafer-type butterfly valve fits ANSI and DIN flanges for easy installation.

• Compact electric-operated valve saves space in tight layouts.

• The EPDM-lined valve allows quick seat and disc replacement.

• The coated cast iron valve resists corrosion for long service life.

4. Application Versatility & Compliance

• The motorized butterfly valve suits HVAC, irrigation, chemical, and water systems.

• Performs reliably across wide temperature ranges.

• Certified with CE, RoHS, ISO 9001, ensuring quality and safety.

• Optional fire-safe and IP67 actuator protection for harsh environments.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1.What steps help prevent actuator or seal failure in the motorized cast iron EPDM butterfly valve?

• Match actuator torque to valve requirements to avoid motor overload or wear.

• Ensure the EPDM liner is compatible with fluid type and temperature range.

• Align the ISO 5211 mounting pad and stem coupling correctly to prevent disc misalignment.

• Inspect actuator housing regularly to prevent moisture or dust ingress.

2.How does the cast-iron body and EPDM seat affect performance of the electric actuated butterfly valve?

• The cast iron housing provides strength and durability for HVAC and water systems.

• The EPDM seat is suitable for water, mild chemicals, and air but not strong acids or solvents.

• The combination supports moderate pressure and temperature with reliable sealing.

• Alternative materials are recommended for seawater, abrasive, or high-temperature media.

3.What installation issues should be avoided for the wafer-type motorized butterfly valve?

• Install in the correct flow direction to prevent seat or disc damage.

• Leave space for actuator wiring and manual override access.

• Avoid oversizing; correctly sized valves improve control and extend actuator life.

• Check flange flatness and gasket condition to prevent leakage at the wafer interface.

4.How does the electric actuator improve efficiency of the automated cast iron EPDM butterfly valve?

• Enables remote or modulating control to reduce manual operation.

• Multi-voltage design allows easy integration into automation systems.

• Calibrate limit switches and position feedback for accurate valve operation.

• Keep the manual override accessible for safe use during power failure.