FLE-D-CFW Electric Cast Iron Wafer PTFE Butterfly Valves

FLE-D-CFW Electric Cast Iron Wafer PTFE Butterfly Valves

Fleyenda Electric Cast Iron Wafer PTFE Butterfly Valve is designed with a fluorine-based PTFE soft sealing lining that provides excellent chemical resistance and reliable leakage prevention. The tight seal between the disc and lining ensures stable performance even under high pressure. Available in sizes DN50–DN600, the valve body can be made of cast iron, CF8, CF8M, or carbon steel, with discs in cast iron or stainless steel.

Technical Specifications

| Size Range | DN50–DN600 (2″–24″) |

| Working Pressure Range: | PN10–PN16 / 150 PSI |

| Working Temperature Range: | -20°C to +180°C |

| Body Material: | Cast Iron |

| Connection Type: | Wafer Type |

| Applicable Medium: | Corrosive fluids, water, acids, alkalis, solvents, seawater |

| Actuator Type: | Electric On/Off or Modulating |

| Voltage Options | AC110V, AC220V, AC380V, DC24V |

| Design Standard | ISO 5211, MSS SP-67 |

| Testing Standard | API 598, EN 12266-1 |

| Fire-Safe Design | Optional |

| Certification | CE / ROHS / ISO / SIL / TUV /IP68 Waterproof |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

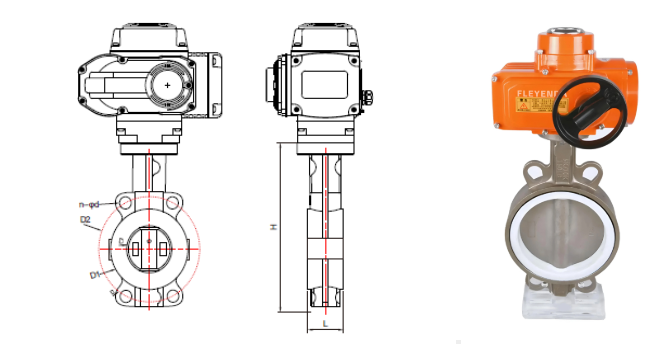

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Corrosion Resistance & Material Reliability

• Electric Cast Iron Wafer PTFE Butterfly Valve uses a full PTFE lining to resist acids, alkalis, and corrosive fluids.

• Epoxy-coated cast iron body provides strong protection against rust and wear.

• PTFE seat and disc ensure smooth operation and tight sealing.

• Suitable for chemical plants, water systems, and food-grade pipelines.

2. Automation & Control Precision

• Electric actuator enables accurate flow regulation and automatic shutoff.

• Supports modulating and on/off control for industrial automation.

• Manual override ensures operation during power loss.

• High-torque motor maintains stable sealing under pressure.

3. Installation & Maintenance Efficiency

• Wafer connection fits PN10/PN16 or ANSI150 flanges for quick installation.

• Compact and lightweight design reduces pipeline stress.

• PTFE lining prevents corrosion and leakage, lowering maintenance.

• Easy replacement of actuator and seat shortens downtime.

4. Safety & Compliance Assurance

• Actuator meets IP67/IP68 protection standards for harsh environments.

• Tested per API 598 and EN 12266-1 for zero leakage.

• Certified with CE, RoHS, and ISO9001 for global compliance.

• Electric drive eliminates air leaks and noise, improving safety.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1.What advantages does the Electric Cast Iron Wafer PTFE Butterfly Valve offer in corrosive chemical environments?

• PTFE lining provides strong resistance to acids, alkalis, and solvents, extending service life.

• Cast iron body ensures durability and mechanical strength under harsh operating conditions.

• Low-friction sealing delivers tight shutoff and stable torque performance.

• Ideal for automated chemical, water treatment, and industrial systems requiring corrosion control.

2.How to ensure proper installation and reliable performance of this motorized wafer butterfly valve?

• Align flanges accurately and apply the correct torque to protect the liner and disc.

• Confirm that working pressure, temperature, and media meet the valve’s rated limits.

• Choose a correctly sized electric actuator to provide sufficient torque for operation.

• Inspect the liner and actuator connections periodically to prevent downtime.

3.How does the electric actuated butterfly valve improve automation and control efficiency?

• Enables remote and automatic flow control in industrial systems.

• Supports modulating or on/off control for precise flow regulation.

• Eliminates the need for pneumatic systems, reducing air leaks and energy loss.

• Compact wafer design simplifies retrofitting and shortens installation time.

4.Why is this PTFE-lined butterfly valve suitable for high-purity or sanitary applications?

• Fluoropolymer lining provides a smooth, non-contaminating interior surface.

• Wafer configuration reduces dead zones, supporting CIP cleaning.

• Electric operation offers repeatable, precise opening and closing cycles.

• Corrosion-proof structure maintains hygienic and stable performance over time.