FLE-Q-TG3 Way Threaded High Pressure Electric Ball Valve

FLE-Q-TG3 Way Threaded High Pressure Electric Ball Valve

The 3 Way Threaded High Pressure Electric Ball Valve features a durable stainless-steel T/L-port design rated up to 1000 PSI, delivering accurate flow control and leak-free operation under high pressure. It ensures dependable automation, extended service life, and proven quality backed by API 598 testing and CE/ISO 9001 certification.

Technical Specifications

| Size Range | ¼” – 4″ (DN8 – DN100) |

| Working Pressure Range: | Up to 1000 PSI (6.4 MPa) |

| Working Temperature Range: | –20°C to +180°C (–4°F to +356°F) |

| Body Material: | Stainless Steel 304 / 316 / 316L |

| Connection Type: | Female NPT / BSP / BSPT Threaded Ends |

| Applicable Medium: | Water, Oil, Gas, Steam, Chemical Solvents, Corrosive Liquids |

| Actuator Type: | Electric Quarter-Turn Actuator |

| Voltage Options | AC110V, AC220V, AC380V, DC24V |

| Design Standard | ASME B16.34 / GB/T 12237 / API 6D |

| Testing Standard | API 598 / EN 12266-1 |

| Fire-Safe Design | API 607 / ISO 10497 |

| Certification | CE / ROHS / ISO / SIL / TUV /IP68 Waterproof |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

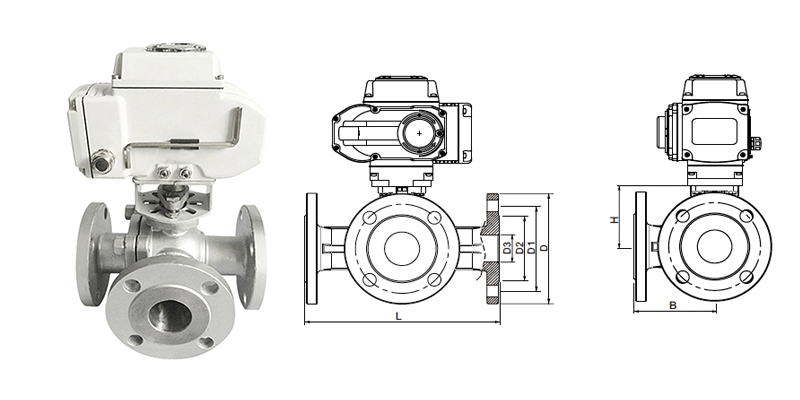

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

High-Pressure Performance & Reliability

• The 3 Way Threaded High Pressure Electric Ball Valve provides reliable sealing up to 1000 PSI.

• T-port or L-port design allows accurate flow direction or mixing control.

• Electric actuator ensures stable quarter-turn motion for precise automation.

• Stainless-steel body with PTFE/PPL seats maintains sealing under high temperature and pressure.

Automation & Process Efficiency

• Supports on/off and modulating control for integration into automation systems.

• Multiple AC/DC voltage options fit various control environments.

• Fast actuator response improves process speed and reduces downtime.

• Feedback and position indicators enable remote monitoring and adjustment.

Material Strength & Application Flexibility

• 316/316L stainless steel resists corrosion from chemicals, gas, and steam.

• Threaded connection allows quick installation without welding.

• Suitable for water, oil, air, and corrosive fluids across industries.

• Explosion-proof and waterproof actuators ensure reliability in harsh sites.

Safety & Compliance

• Fire-safe design meets API 607 / ISO 10497 standards.

• Pressure-tested to API 598 / EN 12266-1 for leak-tight assurance.

• Certified with CE, RoHS, and ISO 9001 for global compliance.

• Compact actuator reduces manual operation risks in high-pressure systems.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

How do I verify that the 3 Way Threaded High Pressure Electric Ball Valve is suitable for high-pressure automation systems?

• Confirm the valve’s pressure rating meets or exceeds system pressure to prevent leakage and ensure durability.

• Check electric actuator compatibility with voltage and control signal requirements for smooth automation.

• Ensure the threaded connection type matches installation needs for secure, space-saving setups.

• Verify the stainless steel body and seat materials can handle corrosive or high-temperature fluids.

What installation and maintenance steps ensure stable operation of the 3 Way Threaded High Pressure Electric Ball Valve?

• Tighten threaded ends to the correct torque to prevent leaks under pressure.

• Match actuator wiring and voltage options with system requirements for reliable operation.

• Inspect seals, seats, and feedback signals regularly to detect early wear or misalignment.

• Confirm 3-way flow configuration (L-port or T-port) suits the intended flow switching or mixing application.

Why choose a three-way design for the 3 Way Threaded High Pressure Electric Ball Valve instead of a two-way valve?

• The 3-way ball design enables flow diversion or mixing to simplify complex piping systems.

• Threaded connection allows fast installation and replacement in compact equipment.

• Electric actuation provides remote control and automation in high-pressure systems.

• Reduces valve quantity and pipeline joints, improving efficiency and reliability.

How can I ensure the 3 Way Threaded High Pressure Electric Ball Valve meets safety and compliance standards?

• Confirm the valve passes high-pressure and leak tests under recognized industrial standards.

• Check certifications such as CE or ISO for regulatory compliance.

• Use suitable materials and seals for high-temperature or corrosive media to maintain safety.

• Perform periodic tests on actuator response and flow direction control to verify stability.