Fleyenda AT Series Pneumatic Actuator

Fleyenda AT Series Pneumatic Actuator

The Fleyenda AT Series Pneumatic Actuator delivers precise and fast valve automation with a dual-piston rack-and-pinion design. It supports double-acting and single-acting (spring return) modes, offers adjustable rotation angles, and complies with ISO5211, DIN3337, and NAMUR standards. Ideal for driving ball valves and butterfly valves in industrial, HVAC, and water treatment applications.

Technical Specifications

| Output Torque Range | 10 Nm – 4000 Nm |

| Rotation Angle | 90° ± 5° adjustable |

| Ambient Temperature Range | −20 °C to +80 °C |

| Body Material | Hard-anodized aluminum alloy |

| Connection Standard | ISO 5211 / NAMUR VDI/VDE 3845 |

| Actuator Type: | Rack and pinion, double-acting or spring-return |

| Voltage Options | 24 V DC (for solenoid valve control) |

| Control Signal Type | 3/2-way or 5/2-way pneumatic; 4–20 mA or 0–10 V with positioner |

| Protection Grade | IP65 / IP67 (optional IP68) |

| Design Standard | ISO 5211 / EN 15714-3 |

| Testing Standard | ISO 9001 / EN 12266 / API 598 |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

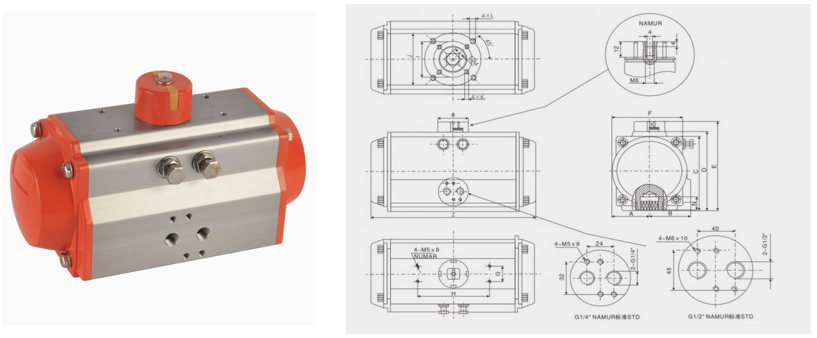

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Performance & Reliability

• High-Torque Pneumatic Actuator: Provides torque up to 4000 Nm for stable valve automation in industrial systems.

• Accurate Valve Positioning: Air-operated actuator ensures precise 90° rotation for on/off or throttling control.

• Corrosion-Resistant Housing: Hard-anodized aluminum body resists wear in chemical, oil & gas, and water applications.

• Fail-Safe Design: Spring-return air actuator closes valves automatically during air loss for safety.

2. Energy Efficiency & Automation

• Compressed-Air Efficiency: Pneumatic control actuator uses low energy with fast response for automation systems.

• Quick Operation Speed: Enables rapid valve movement for high-cycle process control.

• Low Friction Performance: Rack-and-pinion actuator transfers air pressure efficiently and reduces wear.

• Smart Positioner Integration: Works with electro-pneumatic control (4–20 mA or 0–10 V) for intelligent operation.

3. Environmental & Safety Assurance

• Wide Temperature Range: Industrial air actuator operates from −40 °C to +150 °C in harsh environments.

• Explosion-Proof Protection: Certified ATEX and SIL 2 for safe use in hazardous areas.

• IP67 Waterproof Protection: Pneumatic rotary actuator prevents dust and water damage outdoors.

• Anti-Corrosion Coating: Epoxy and stainless-steel parts extend service life in corrosive conditions.

4. Flexibility & Customization

• Universal Mounting: Follows ISO 5211 and NAMUR VDI/VDE 3845 for all common valve actuator setups.

• Custom Torque Range: Adjustable from low to high torque for industrial applications.

• Surface Coating Options: PTFE, nickel, or anodized finishes enhance chemical resistance.

• Flexible Actuation Type: Supports double-acting, spring-return, and hybrid systems for flow control.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What factors determine how fast a Pneumatic Actuator can operate?

• Cycle speed depends on air pressure, bore size, and flow rate within the system.

• Rotary types are affected by travel angle and spring tension in spring-return models.

• Smooth airflow through valves and flow controllers improves actuation response.

• Proper sizing and precise alignment reduce friction and ensure consistent performance.

2. How do I choose the right size and mounting for my Pneumatic Actuator?

• Determine valve torque and rotation angle before selecting actuator size.

• Match the mounting interface to ISO 5211 or NAMUR VDI/VDE 3845 standards.

• Choose quarter-turn, multi-turn, or linear actuation based on valve type.

• Select between double-acting and spring-return types depending on safety needs.

3. What maintenance extends the lifespan of a Pneumatic Valve Actuator?

• Keep compressed air clean, dry, and oil-free to protect seals and bearings.

• Inspect seals, bolts, and end-caps regularly to prevent air leakage or corrosion.

• Monitor actuator stroke and travel stops for wear or misalignment.

• Use proper lubrication and ensure filters are maintained for smooth cycling.

4. Can a Pneumatic Actuator work in harsh or hazardous environments?

• Industrial-grade models operate under extreme temperatures, moisture, and dust.

• Check IP65/IP67 protection for outdoor or corrosive applications.

• Use ATEX or SIL-certified versions for explosive or safety-critical zones.

• Select corrosion-resistant coatings and materials for chemical or marine use.