Fleyenda FLE Series Electric Actuator

Fleyenda FLE Series Electric Actuator

Fleyenda FLE series electric actuators provide precise 0–90° control for butterfly, ball, and damper valves. Available in ON/OFF, regulating, and intelligent types, they deliver high torque up to 4000 Nm and support AC/DC power with 4–20mA or 0–10V control signals. Optional features include IP68 protection, explosion-proof design, and power-off reset, ensuring reliable and efficient valve operation.

Technical Specifications

| Output Torque Range | 50 Nm – 3000 Nm |

| Rotation Angle | 0° – 90° (±5° adjustable) |

| Ambient Temperature Range | -20°C to +70°C |

| Body Material | Die-cast Aluminum Alloy with Powder-Coated Finish |

| Connection Standard | ISO 5211 Direct Mounting Interface |

| Actuator Type: | Quarter-turn Electric Actuator |

| Voltage Options | AC 220 V / AC 110 V / DC 24 V |

| Control Signal Type | On/Off (2-position) or Modulating (4–20 mA / 0–10 V) |

| Protection Grade | IP67 (Optional IP68 for waterproof applications) |

| Design Standard | IEC 60034 / ISO 5211 / EN 60529 |

| Testing Standard | ISO 9001 Quality System & CE / RoHS Compliance |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

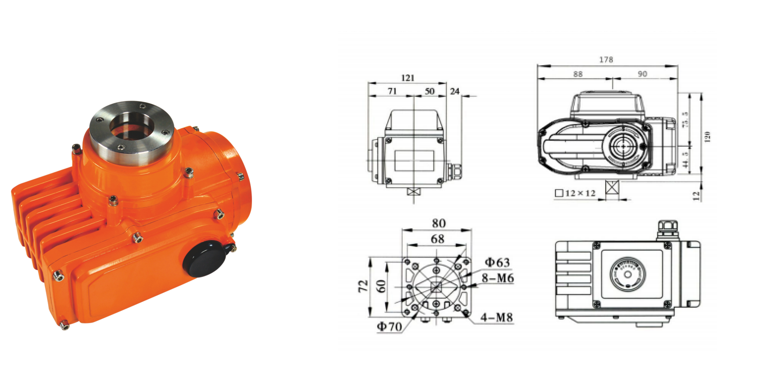

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Precision & Control Performance

• Electric actuator delivers 50–3000 Nm torque for accurate valve movement and reliable flow automation.

• Intelligent limit sensors and feedback modules enable precise open/close control for industrial valve automation.

• Adjustable 0–90° rotation ensures smooth flow regulation and reduces pressure shock.

• Modulating actuator (4–20 mA / 0–10 V) integrates with PLC or DCS for process control in chemical and energy systems.

2. Reliability & Durability

• Aluminum alloy housing with anti-corrosion coating ensures long service life for motorized actuator.

• IP65 protection keeps electric valve actuator stable in humid or outdoor environments.

• Built-in thermal and overload protection prevents motor damage and reduces downtime.

• Self-locking gear design maintains valve position during power failure for safety.

3. Installation & Compatibility

• ISO 5211 interface allows electric actuator motor to mount directly on ball, butterfly, or plug valves.

• Compact body simplifies installation in HVAC and water-treatment systems.

• Multi-voltage options (AC220V, AC110V, AC380V, DC24V) fit global industrial automation setups.

• Manual override supports on-site operation during power loss.

4. Smart Automation & Maintenance Efficiency

• Position indicator and LED display provide real-time valve status for efficient valve control.

• Electric drive reduces energy cost compared to pneumatic systems.

• Communication modules (Modbus, Profibus) connect electric motor actuator to smart networks.

• Modular structure enables quick maintenance and part replacement.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What are the key considerations when selecting an electric actuator for industrial valve automation systems?

• Evaluate required torque and valve size to ensure the electric actuator can handle full open/close loads.

• Confirm ISO 5211 mounting compatibility between actuator and valve.

• Check IP65+ protection and temperature range for electric valve actuator in harsh environments.

• Choose between on/off or modulating control for precise integration with automation systems.

2. How does an electric actuator compare to pneumatic or hydraulic systems?

• Electric actuators eliminate air or fluid systems, reducing energy use and maintenance.

• Provide precise and repeatable positioning for accurate flow control.

• Offer cleaner operation with no leaks, ideal for sterile or indoor applications.

• Pneumatic options may still perform better in ultra-fast or high-cycle applications.

3. What maintenance practices extend the service life of an electric actuator?

• Inspect electrical connections, seals, and gear alignment regularly.

• Keep the motorized actuator clean and protected from moisture or dust.

• Test manual override periodically to ensure operation during power loss.

• Watch for unusual noise or vibration indicating wear or misalignment.

4. Can an electric actuator be used outdoors or in hazardous environments?

• Use models with ATEX or explosion-proof certification for hazardous areas.

• Ensure enclosure rating of IP65 or higher for outdoor use.

• Select corrosion-resistant materials for chemical or marine applications.

• Confirm manual override and feedback remain reliable in extreme conditions.