F-ZJHP Single Seat Control Valve

F-ZJHP Single Seat Control Valve

The Single Seat Control Valve uses a precision single-plug design for accurate flow control and tight shut-off, improving process stability and reducing energy loss; made of corrosion-resistant stainless steel and tested to API 598 and IEC 60534, it ensures reliable operation in chemical, steam, and water systems.

Technical Specifications

| Size Range | DN15 – DN300 (½″ – 12″) |

| Working Pressure Range: | PN16 – PN100 (ANSI 150 – 600 Class) |

| Working Temperature Range: | (−40 °F to +842 °F) — varies with body and trim material |

| Body Material: | WCB / CF8 / CF8M / CF3M / Cast Iron / Bronze (optional per medium) |

| Connection Type: | Flanged (ASME B16.5 / DIN PN Standards) or Threaded (NPT / BSP) |

| Applicable Medium: | Steam, Water, Oil, Air, Gas, Corrosive Liquids (Chemical Process Media) |

| Actuator Type: | Pneumatic Diaphragm Actuator (Linear Type) with Positioner |

| Voltage Options | 24 V DC / 110 V AC / 220 V AC |

| Design Standard | IEC 60534 / GB/T 4213 / ANSI B16.34 |

| Testing Standard | API 598 / GB/T 13927 / ISO 5208 Leakage Class IV (V available optional) |

| Fire-Safe Design | Optional (API 607 Compliant) |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

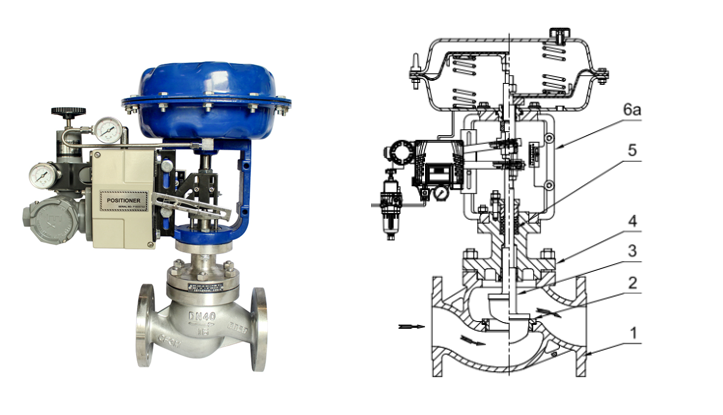

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Precision Flow Control & Performance

• High-Accuracy Regulation – The single seat control valve provides precise flow modulation with low hysteresis for stable process automation.

• Tight Shut-Off – Precision trim achieves Class IV–V sealing, improving reliability in flow control applications.

• Fast Response – The pneumatic actuator and smart positioner deliver quick response to pressure or load variations.

• Flexible Flow Characteristics – Linear or equal-percentage options suit steam, air, gas, and liquid media.

2. Durability & Reliability in Harsh Environments

• Corrosion-Resistant Body – Stainless steel or carbon steel construction withstands corrosion and erosion in demanding conditions.

• High Temperature & Pressure Capability – Operates up to 450 °C and 100 bar for chemical, power, and oil & gas industries.

• Long Service Life – Hardened trim reduces wear and cavitation for extended durability.

• Certified Safety – Complies with API 607, ISO 9001, and CE standards for fire-safe, globally accepted performance.

3. Operational Efficiency & Cost Optimization

• Low Maintenance – Simple single-seat structure enables quick inspection and part replacement, cutting maintenance costs.

• Energy-Efficient Actuation – Pneumatic diaphragm actuator reduces air consumption while maintaining accurate flow regulation.

• Stable Output – Smooth control minimizes vibration and pressure fluctuation in pipelines.

• Compact High-Cv Design – Large flow capacity within a compact body enhances pipeline efficiency.

4. Automation Compatibility & System Integration

• Smart Positioner Integration – Supports 4–20 mA and HART signals for modern control systems.

• Multi-Voltage Options – Operates on 24 VDC, 110 VAC, or 220 VAC for flexible industrial automation setups.

• Standard Mounting Interface – Easily integrates with PLC and DCS systems.

• Wide Media Adaptability – Suitable for water, oil, steam, and chemical process applications.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. How do I choose the right Single Seat Control Valve for high-pressure or modulating service?

• Evaluate the pressure drop (ΔP) to keep the valve within its stable operating range.

• Use the correct Cv or Kv value based on required flow, pressure, and medium.

• Match actuator thrust and positioner capacity to unbalanced plug forces in single-seat designs.

• Confirm temperature, medium compatibility, and voltage options meet process and automation standards.

2. What are common issues with Single Seat Control Valves in steam or chemical applications?

• Seat wear, cavitation, and corrosion are frequent problems under high temperature or aggressive media.

• Leakage results from seat degradation; periodic trim replacement ensures tight shut-off.

• Continuous operation at extreme positions reduces control accuracy—maintain balanced flow conditions.

• Regular actuator calibration prevents sticking and improves modulation accuracy.

3. How does a Single Seat Control Valve compare with other valve types?

• Provides tighter shut-off and simpler trim than double-seat or cage-guided valves.

• Requires larger actuator torque due to higher unbalanced forces.

• Offers more predictable control performance and easier loop tuning in automation systems.

• Best suited for precise throttling and low-leakage applications rather than extreme-pressure service.

4. What installation and automation factors affect Single Seat Control Valve performance?

• Maintain straight piping runs to stabilize flow and minimize turbulence.

• Calibrate actuators and smart positioners to ensure accurate signal-to-motion response.

• Integrate feedback and fail-safe logic with PLC or DCS systems for reliable automation.

• Verify valve travel, leakage class, and hysteresis after installation to confirm performance.