F-ZJHS Pneumatic Angle Control Valve

F-ZJHS Pneumatic Angle Control Valve

The Angle Control Valve uses a 90° flow path to reduce turbulence and cavitation, providing precise flow control, lower erosion, longer service life, and verified performance under IEC 60534 and API 598 standards.

Technical Specifications

| Size Range | DN15–DN300 (½”–12″) |

| Working Pressure Range: | PN1.6–6.4MPa / ANSI Class150–600 |

| Working Temperature Range: | −40°C–+450°C |

| Body Material: | WCB / CF8 / CF8M / CF3M |

| Connection Type: | Flanged / Welded |

| Applicable Medium: | Steam, Gas, Oil, Water, Corrosive Fluids |

| Actuator Type: | Pneumatic Diaphragm / Electric |

| Voltage Options | AC220V / AC110V / DC24V |

| Design Standard | IEC 60534 / ISA S75 / GB/T 4213 |

| Testing Standard | GB/T 13927 / API 598 / ISO 5208 |

| Fire-Safe Design | API 607 / ISO 10497 |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

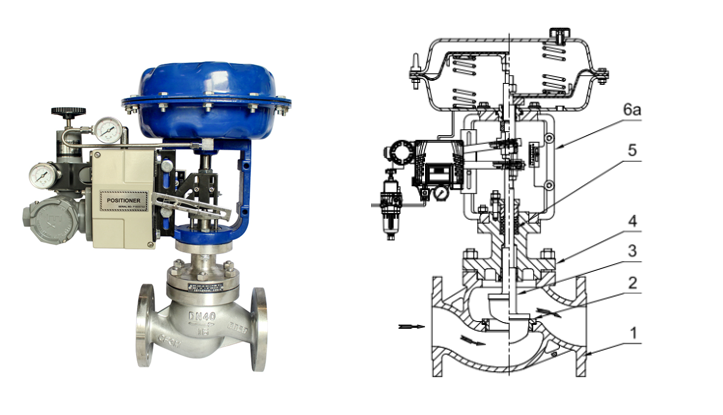

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Precision Flow Control & Performance

• Angle Control Valve ensures accurate flow regulation under variable pressure.

• Angle body valve design reduces turbulence and energy loss.

• High Cv capacity delivers precise proportional control in automation systems.

• Pneumatic actuator provides fast, stable response for reliable process control.

2. Durability & Anti-Erosion Construction

• 90° angle valve flow path minimizes cavitation and erosion.

• Stainless steel body and hardened trim resist corrosion and wear.

• Suitable for steam, gas, and corrosive fluids in harsh environments.

• Fire-safe control valve structure meets API and ISO safety standards.

3. Energy Efficiency & Cost Optimization

• Pneumatic diaphragm valve uses minimal air for low energy consumption.

• Optimized internal geometry reduces pressure drop and improves flow efficiency.

• Long service life lowers maintenance cost and downtime.

• Compact industrial valve design saves installation space.

4. Automation Integration & Flexibility

• Compatible with digital positioners and smart control systems.

• Supports pneumatic, electric, and electro-pneumatic actuation.

• Modular design adapts to different process control conditions.

• Multiple valve materials and standards fit global pipeline systems.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What factors determine the best sizing for an Angle Control Valve in industrial flow systems?

• Accurate flow rate and differential pressure calculation prevent oversizing or unstable modulation.

• Proper Cv selection ensures smooth throttling and stable operation.

• The angle-body design optimizes pressure recovery and flow direction.

• Correct actuator choice maintains responsiveness and precise automation control.

2. How does an industrial angle valve reduce cavitation and erosion in high-pressure applications?

• The 90° angle flow path minimizes turbulence and internal wear.

• The angle-body structure discharges vapor efficiently in flashing conditions.

• Hardened trim materials resist corrosion and extend service life.

• The anti-cavitation design maintains pressure balance and protects outlets.

3. What installation tips ensure the angle-type control valve operates at peak performance?

• Follow proper flow direction to maintain correct velocity and pressure.

• Use suitable pneumatic or electric actuators with fail-safe positioning.

• Calibrate valve positioners to ensure stable control and reduce hunting.

• Maintain straight-pipe sections and vibration isolation to reduce noise.

4. What maintenance practices improve reliability and lifespan of an angle-body control valve?

• Inspect valve trim for corrosion, wear, or cavitation damage.

• Keep actuator linkages clean and properly calibrated.

• Monitor pressure drop and flow velocity to detect early issues.

• Use erosion-resistant coatings for severe service environments.