F-ZJHF Pneumatic Lined Control Valve

F-ZJHF Pneumatic Lined Control Valve

The Lined Control Valve with PTFE/PFA lining delivers precise flow control and corrosion resistance in acidic and alkaline systems, ensuring leak-free operation, extended service life, and verified reliability under API 598 and IEC 60534 standards.

Technical Specifications

| Size Range | DN15 – DN300 (½″ – 12″) |

| Working Pressure Range: | PN10 – PN16 / 150 PSI |

| Working Temperature Range: | −20 °C to +180 °C |

| Body Material: | Cast Iron / Carbon Steel / Stainless Steel with PTFE or PFA lining |

| Connection Type: | Flanged (EN 1092-1, ASME B16.5, JIS B2220) |

| Applicable Medium: | Corrosive liquids, acids, alkalis, chlorine, solvents, wastewater |

| Actuator Type: | Pneumatic diaphragm actuator |

| Voltage Options | 24 V DC / 110 V AC / 220 V AC |

| Design Standard | IEC 60534 / GB/T 4213 / ANSI B16.34 |

| Testing Standard | API 598 / EN 12266-1 |

| Fire-Safe Design | Not applicable |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

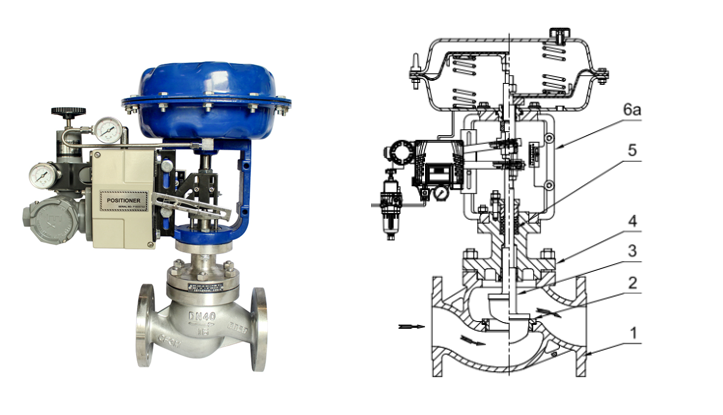

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Precision Flow Control Performance

• Lined Control Valve provides stable, precise regulation for chemical process control and industrial automation.

• PTFE-lined valve body ensures smooth flow and accurate throttling with minimal pressure loss.

• Pneumatic actuator offers fast response and precise modulation under corrosive conditions.

• Fluorine-lined control structure maintains flow accuracy in demanding operations.

2. Corrosion and Chemical Resistance

• PTFE/PFA lined valve isolates metal parts, preventing corrosion from acids, alkalis, and chlorine.

• Anti-permeation design protects pipelines in chemical and wastewater treatment systems.

• Ideal for acid-resistant flow control with zero leakage and long-term reliability.

• Performs stably in sulfuric acid, hydrochloric acid, and caustic soda applications.

3. Maintenance and Operational Efficiency

• Lined pneumatic control valve uses modular structure for quick installation and maintenance.

• Self-cleaning design prevents residue buildup and maintains valve precision.

• Lightweight body suits automated pipeline systems with limited space.

• Long cycle life lowers maintenance cost and increases uptime.

4. Safety and Compliance Assurance

• Complies with IEC 60534, API 598, and EN 12266-1 standards.

• Non-metallic lining prevents sparks in chemical flow control applications.

• Leakage class VI sealing protects operators and environment.

• Certified ISO 9001, CE, RoHS, and ATEX for hazardous environments.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What corrosive media can a Lined Control Valve safely handle in chemical process systems?

• The Lined Control Valve is ideal for corrosive fluid regulation in chemical manufacturing and acid-resistant flow systems, using PTFE or PFA lining to block acid and alkali attack.

• Its fluoropolymer-lined body resists hydrochloric acid, sulfuric acid, caustic soda, and other aggressive chemicals.

• This corrosion-proof control valve prevents metal contamination and leakage.

• Widely used in chemical dosing, chlor-alkali, and pharmaceutical plants requiring zero leakage.

2. How does a Lined Control Valve improve flow accuracy and process stability?

• The fluorine-lined control valve uses a high-precision pneumatic actuator and positioner for responsive flow adjustment.

• Its smooth PTFE surface minimizes turbulence and pressure loss in industrial automation systems.

• Adjustable flow characteristics ensure precise control in acidic or solvent pipelines.

• Maintains consistent output and stable operation in chemical process control.

3. What maintenance advantages does a PTFE-Lined Control Valve offer?

• The lined regulating valve has a modular design for quick service and reduced downtime.

• The non-stick lining prevents residue buildup, keeping the flow path clean.

• Lightweight structure simplifies actuator alignment and replacement.

• Long service life lowers maintenance costs in wastewater and chemical systems.

4. What are the pressure and temperature limits of a Fluorine-Lined Control Valve?

• PTFE/PFA-lined valves operate from –20 °C to +180 °C and up to PN16 (150 PSI).

• The lined valve body maintains sealing under fluctuating pressure or temperature.

• Proper sizing ensures stable flow and prevents liner deformation.

• Suitable for acid-resistant control applications in harsh environments.