Fleyenda CF8 CF8M Pneumatic Control Valves

Fleyenda CF8 CF8M Pneumatic Control Valves

The pneumatic control valve is composed of an actuator and an adjustment mechanism The actuator is the thrust component of the adjustment valve. The valve body is the regulating component of the pneumatic regulating valve It directly contacts the regulating medium to regulate the flow, pressure, temperature and other process parameters of the fluid. Without additional explosion-proof measures.

Application: petroleum, chemical, electric power, metallurgy, etc.

Technical Specifications

Pneumatic Actuator Features

- Corrosion resistance: After 1,000,000 cycles of life test, the performance is still reliable. Using high-quality material and metal coating treatment, strong corrosion resistance and longer service life.

- Larger Size: Longer air cylinder, higher air consumption

- Low and High Temperature Resistance: Lower to 30℃/86℉~Up to 180℃/356℉

- Certificate Insurance: ISO 5211 and Namur international installation standard, easy to install and maintain.

Technical Parameters of Pneumatic Control Valve

| Size Range | DN20 to DN400(3/4″ to 16″) |

| Body Material | WCB/ SS304/SS316(CF8/CF8M) |

| Spool | SS304/SS316 |

| Seat Material | SS304/SS316 |

| Connection Type | Flange (GB/ANSI/JIS/DIN) |

| Pressure Rating | 0.6, 1.6, 4.0, 6.4MPa; 150Lb, 300Lb, 600Lb; 10K, 20K, 30K 40k |

| Temperature Of Medium | -60°C to 450°C (-140°F to 842°F) |

| Optional Accessories | Solenoid Valve, Positioner, Limit Switch, F.R.L., Manual Device |

| Applications | HVAC Systems, Water Treatment, Food Processing, Chemical Industries etc |

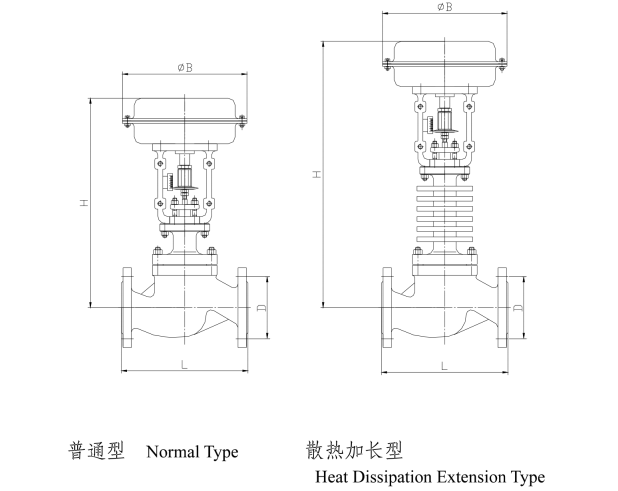

Pneumatic Control Valve Main Outline and Structure

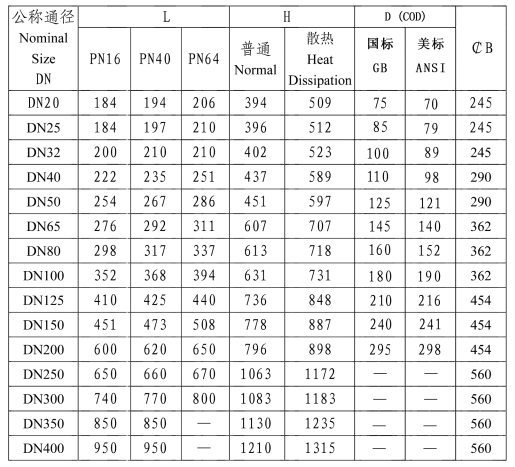

Pneumatic Control Valve Dimensions

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures