FLE-ZZYP self-operated pressure control valve

FLE-ZZYP self-operated pressure control valve

The Self-Operated Pressure Control Valve uses a self-driven diaphragm to control pressure without external power, ensuring stable flow and efficiency for steam, gas, and liquid systems, reducing maintenance costs, and offering reliability under 6.4 MPa and 350 °C with API 598 and ISO 9001 certification.

Technical Specifications

| Size Range | DN15–DN300 (½”–12″) |

| Working Pressure Range: | 0.1–6.4 MPa |

| Working Temperature Range: | -20°C to +350°C |

| Body Material: | Cast Steel / Stainless Steel (CF8, CF8M, WCB) |

| Connection Type: | Flanged |

| Applicable Medium: | Steam, Air, Water, Gas, Oil |

| Actuator Type: | Self-operated diaphragm actuator |

| Voltage Options | Not applicable |

| Design Standard | GB/T 12246, ANSI/API 520, DIN EN 334 |

| Testing Standard | GB/T 13927, API 598, EN 12266-1 |

| Fire-Safe Design | Optional per API 607 |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

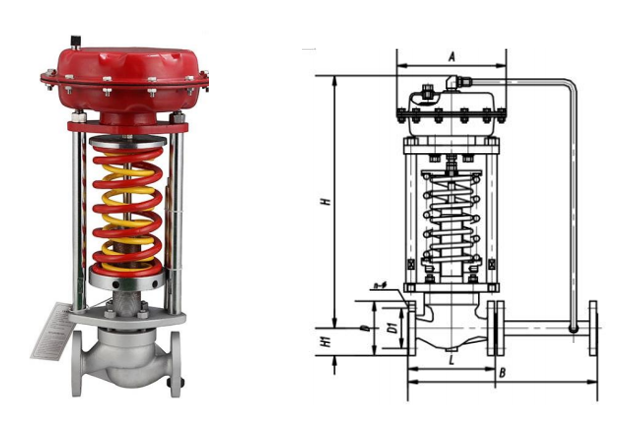

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Pressure Stability & Energy Efficiency

• Self-Operated Pressure Control Valve maintains stable outlet pressure without power or air supply.

• Automatic pressure regulating valve lowers energy consumption using medium pressure as the driving force.

• Protects steam and gas systems from pressure surges and vibration damage.

• Ensures consistent performance in chemical, water treatment, and heating systems.

2. Installation Flexibility & Maintenance-Free Design

• Self-regulating control valve features compact structure and easy installation.

• No wiring or pneumatic line needed, ideal for industrial pressure regulation systems.

• Modular design allows quick maintenance and seal replacement.

• Durable stainless steel or carbon steel body resists corrosion and wear.

3. Broad Media & Application Compatibility

• Suitable for steam, air, water, gas, and oil in diverse industrial applications.

• Reliable under high temperature and pressure in boiler and process systems.

• Used across chemical, HVAC, petroleum, and power industries.

• Compatible with ANSI, DIN, and JIS flanges for global installation.

4. Operational Safety & Precision Control

• Self-operated regulator valve provides fast feedback and accurate flow control.

• Prevents overpressure and protects downstream equipment.

• Improves safety and stability in automatic pressure control systems.

• Tested per API 598 and EN 12266-1 for leak-free performance.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. How does a Self-Operated Pressure Control Valve maintain stable performance without power or air supply?

• The Self-Operated Pressure Control Valve uses medium energy to regulate outlet pressure automatically.

• Its automatic pressure regulating system balances downstream pressure through a diaphragm mechanism.

• Suitable for remote sites and energy-saving plants, it maintains accuracy under fluctuating inlet conditions.

• This self-acting pressure regulator ensures reliable control for steam, gas, and water systems.

2. How do I select the right model and capacity for a Self-Acting Pressure Regulator?

• Analyze inlet pressure, outlet pressure, and flow to size the automatic pressure control valve correctly.

• Choose corrosion-resistant materials like stainless steel self-operated valves for steam or gas.

• Ensure the pressure reducing valve supports a proper turndown ratio to avoid instability.

• Match flange standards such as ANSI, DIN, or JIS to existing pipelines.

3. Can a Self-Operated Pressure Regulator handle high-temperature or corrosive media?

• High-grade self-operating control valves withstand up to 350 °C and 6.4 MPa.

• A stainless steel pressure control valve resists corrosion in chemical or steam systems.

• Reinforced diaphragms maintain sealing accuracy under temperature changes.

• Suitable for boilers, chemical plants, and industrial steam lines requiring stable pressure.

4. What are common maintenance issues with Automatic Pressure Regulating Valves and how to prevent them?

• Common issues include diaphragm wear, spring fatigue, and pilot blockage.

• Use filters to protect the self-acting valve body from debris.

• Inspect sealing parts regularly to prevent leakage and maintain response accuracy.

• Perform periodic calibration to ensure consistent regulation.