F-ZJHQ Diaphragm 3-way Control Valve

The Diaphragm 3-Way Control Valve uses a pneumatic actuator and three-port body for precise flow control and zero leakage, ensuring efficient mixing or diverting in corrosive or high-temperature systems; its stainless-steel body with PTFE or EPDM diaphragm

Technical Specifications

| Size Range | DN15 – DN300 (½″ – 12″) |

| Working Pressure Range: | 0.6 MPa – 6.4 MPa (6 – 64 bar) |

| Working Temperature Range: | −20 °C to +220 °C (−4 °F to +428 °F) |

| Body Material: | Carbon Steel / Stainless Steel (SS304, SS316) |

| Connection Type: | Flanged / Threaded / Welded (per customer requirement) |

| Applicable Medium: | Steam, Water, Air, Oil, Corrosive Fluids, Chemical Solutions |

| Actuator Type: | Pneumatic Diaphragm Actuator (with Positioner) |

| Voltage Options | 24 VDC / 110 VAC / 220 VAC |

| Design Standard | GB/T 12238 / IEC 534 / ANSI B16.34 / DIN EN 1349 |

| Testing Standard | GB/T 13927 / API 598 / EN 12266-1 |

| Fire-Safe Design | Optional Fire-Safe Construction per API 607 |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

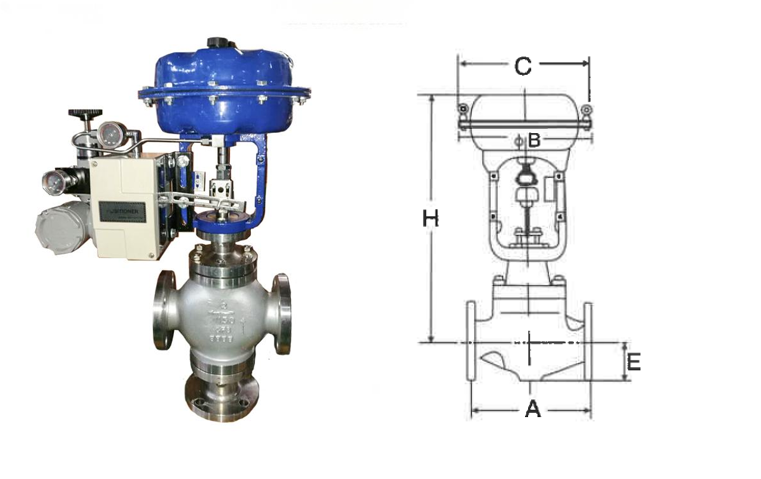

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Precision Flow Control & Performance

• The diaphragm 3-way control valve provides accurate flow adjustment for mixing or diverting operations in industrial process control systems.

• The pneumatic actuator ensures fast response and stable regulation for liquids, gases, and steam.

• Linear or equal percentage flow characteristics deliver smooth modulation, improving process precision and energy efficiency.

• The balanced valve plug minimizes vibration and noise, maintaining reliable operation under variable pressure conditions.

2. Durability & Corrosion Resistance

• High-grade stainless steel or carbon steel body resists corrosion and wear, ideal for chemical and water treatment plants.

• PTFE or EPDM sealing materials provide tight shut-off and temperature stability for aggressive or high-pressure media.

• Anti-corrosive actuator housing ensures long service life in humid or outdoor environments.

• Fire-safe and explosion-proof configurations enhance operational safety in petrochemical and pharmaceutical systems.

3. Easy Maintenance & Efficiency

• Modular pneumatic diaphragm valve design allows quick dismantling for maintenance without removing the entire assembly.

• Standardized actuator interfaces simplify part replacement and reduce system downtime.

• Built-in positioner and feedback options enable seamless integration with automation systems like PLC and DCS.

• Low air consumption in the control actuator lowers operational costs and enhances energy efficiency.

4. Application Versatility & Compatibility

• The 3-way regulating valve supports both diverting and mixing flow functions, optimizing space and cost in industrial pipelines.

• Suitable for water, air, steam, oil, and chemical fluids, serving multiple sectors including HVAC, food, and process automation.

• Available with flanged, threaded, or welded connections to meet ANSI, DIN, and JIS standards.

• Certified under CE, ISO, and API standards, ensuring performance reliability and global compliance for automation projects.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What causes performance issues in a diaphragm 3-way control valve and how can they be avoided?

• Diaphragm wear or fatigue can lead to air leakage and reduced flow accuracy; regular inspection and replacement prevent failure.

• Cavitation and erosion under high differential pressure shorten service life; correct valve sizing avoids this.

• Wrong selection between mixing and diverting types causes unstable flow; confirm configuration before installation.

• Stable air supply and accurate actuator calibration ensure reliable operation.

2. How do I select the correct size and actuator for a 3-way diaphragm control valve?

• Define whether your system requires mixing flow or diverting operation, as this determines port layout.

• Calculate flow coefficient (Cv), pressure range, and temperature to select the proper size.

• Choose a pneumatic actuator for fast response or an electric actuator for precise automation control.

• Match valve body and seat materials with the working medium to improve durability and sealing.

3. Can a 3-way diaphragm valve handle corrosive or high-temperature fluids?

• Yes, the diaphragm-actuated valve isolates the medium from the actuator, ideal for corrosive and clean-in-place systems.

• PTFE, EPDM, or Viton diaphragms provide chemical and thermal resistance.

• Stainless steel or lined carbon steel bodies protect against corrosion in chemical or water treatment applications.

• Proper diaphragm selection ensures tight shut-off and stable operation under extreme conditions.

4. What are the best maintenance practices for a pneumatic 3-way control valve?

• Inspect the diaphragm assembly for cracks or deformation to maintain sealing.

• Check actuator feedback and travel accuracy to prevent positioning errors.

• Monitor for vibration, cavitation, or seat wear as indicators of process imbalance.

• Use genuine spare parts and follow preventive maintenance schedules to reduce downtime.

5. What are the advantages of using one 3-way regulating valve instead of two 2-way valves?

• A single 3-way valve simplifies piping, reduces actuator count, and lowers installation cost.

• It saves space and minimizes potential leakage points.

• Correct port orientation prevents reverse flow and improves efficiency.

• The three-port control valve integrates easily with automation systems for faster response and simpler maintenance.