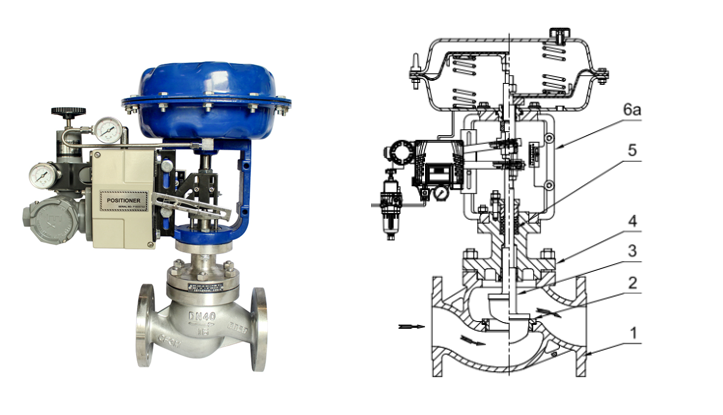

F-ZJHM Stainless Steel Sleeve Control Valve

Stainless Steel Sleeve Control Valve uses a cage-guided sleeve trim to stabilize flow and reduce noise under high pressure; its CF8M stainless steel body resists corrosion and extends service life; this design improves accuracy, lowers cavitation, and cuts maintenance costs, verified by IEC 60534 and API 598 testing for reliability and leak-tightness.

Technical Specifications

| Size Range | DN15–DN300 (1/2″–12″) |

| Working Pressure Range: | ASME Class 150/300/600 (PN16–PN100) |

| Working Temperature Range: | : -10°C to 200°C (PTFE/soft seat); -29°C to 425°C (graphite/metal seat) |

| Body Material: | CF8M (ASTM A351 316/316L Stainless Steel) |

| Connection Type: | Raised-Face Flanged, ASME B16.5 (EN 1092-1 on request) |

| Applicable Medium: | Liquids, gases, and steam (including mildly corrosive service) |

| Actuator Type: | Pneumatic diaphragm, spring-return with electro-pneumatic positioner (4–20 mA) |

| Voltage Options | 24 VDC, 110 VAC, 220 VAC (for positioner/solenoid/limits) |

| Design Standard | IEC 60534; ASME B16.34 |

| Testing Standard | API 598 (body/seat); IEC 60534-4 (performance) |

| Fire-Safe Design | Not standard/applicable for globe control valves |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Precision Flow Control

• Stainless Steel Sleeve Control Valve provides accurate flow regulation with low noise and stable performance.

• Cage-guided trim ensures smooth throttling and minimizes pressure fluctuation.

• Supports both linear and equal-percentage flow for precise process control.

• Suitable for steam, gas, and liquid applications requiring high accuracy.

2. Corrosion & Durability

• CF8M stainless steel body resists corrosion in chemical and marine environments.

• Hardened seat and plug extend service life in erosive and high-temperature systems.

• PTFE or graphite packing maintains tight sealing under thermal stress.

• Ideal for chemical, petrochemical, and refinery pipelines.

3. Automation Integration

• Pneumatic diaphragm actuator with digital positioner enables precise modulation.

• Compatible with 4–20 mA control systems and smart DCS/PLC networks.

• Fast response and low air consumption improve energy efficiency.

• Compact automation-ready design fits limited space installations.

4. Safety & Certification

• Tested to API 598 and IEC 60534 for performance and leak integrity.

• Meets ASME B16.34, CE PED, and ISO 9001 standards.

• Fail-safe spring-return actuator ensures automatic shutdown on power loss.

• Designed for industrial safety compliance across global markets.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1.What factors should be checked when sizing a Stainless Steel Sleeve Control Valve for high-pressure service?

• Confirm valve pressure drop and flow range suit the process conditions.

• Use sleeve-guided trim to handle large differential pressures with stability.

• Match actuator and positioner size to the valve’s flow capacity.

• Choose the right flow characteristic—linear or equal-percentage—to optimize control.

2.How to ensure reliable operation of a corrosion-resistant sleeve control valve in harsh media?

• Verify 316/316L stainless steel body and trim for chemical compatibility.

• Select proper packing—PTFE for moderate, graphite for high-temperature service.

• Use hardened seats for erosion resistance under abrasive or hot flow.

• Schedule regular inspection of sleeve and plug surfaces for wear.

3.What installation steps improve performance of a flanged stainless sleeve valve in automation systems?

• Maintain straight pipeline runs to reduce turbulence.

• Calibrate actuator stroke and positioner response before startup.

• Verify 4–20 mA signal accuracy with control system feedback.

• Test valve performance under operating flow to confirm stability.

4.How to reduce noise or vibration in a high-pressure control valve?

• Keep pressure drop within the valve’s rated ΔP limit.

• Install anti-cavitation sleeve trim for flashing or erosive conditions.

• Inspect downstream piping for restrictions that amplify turbulence.

• Adjust actuator tuning to prevent hunting in control loops.

5.What certifications confirm quality and safety for a stainless sleeve control valve?

• Compliance with ASME B16.34 and IEC 60534 ensures design integrity.

• Leak testing per API 598 validates tight shut-off.

• ISO 9001 and CE PED certification guarantee manufacturing quality.

• Traceable documentation supports industrial and export compliance.