FAW-D-PF AW Pneumatic PTFE Fluorine Lining Flanged Butterfly Valve

The FAW-D-PF AW Pneumatic PTFE Fluorine Lining Flanged Butterfly Valve combines robust AW pneumatic actuator performance with a high-quality PTFE-lined valve body. Designed for industrial automation, this valve provides reliable ON/OFF and modulating control in corrosive and demanding environments. Its flanged connection allows for easy installation in pipelines ranging from DN50 to DN1400, while the PTFE lining ensures chemical resistance and minimal leakage. The valve features durable stem and disc materials, making it suitable for high-temperature and high-pressure applications. Optional accessories, including limit switches and positioners, enable precise remote monitoring and control.

Technical Specifications

Key Features

- AW pneumatic actuator integrated for precise ON/OFF and modulating control

- PTFE fluorine lining ensures excellent chemical resistance and zero leakage

- Flanged connection for easy installation and maintenance

- Wide temperature range compatibility: -10℃ to +150℃ (PTFE)

- Available in ductile iron, cast steel, and stainless steel body options

- Suitable for large diameter valves (DN50-DN1400)

- High-performance stem and disc materials for durability and corrosion resistance

- Optional limit switches and positioners for remote control and feedback

Technical Parameters of FAW-D-PF AW Pneumatic PTFE Fluorine Lining Butterfly Valve

| Butterfly Valve | |

|---|---|

| Nominal Pressure | 1.0 MPa (PN10), 1.6 MPa (PN16), 150LB |

| Nominal Diameter | DN50-DN1400 (50mm-1400mm) |

| Temperature Range | EPDM: -20℃~+120℃ NBR: -20℃~+93℃ PTFE: -10℃~+150℃ |

| Body Material | Ductile Iron, Cast Steel, Stainless Steel |

| Disc Material | Ductile Iron, Stainless Steel, Aluminum Bronze C954, Rubber Lined, Nylon, PTFE, etc. |

| Stem Material | Q235, 45#, 2Cr13, 304, 316 |

| Seat Material | EPDM, NBR, PTFE, SI (Silicone) |

| AW Series Electric Actuator | |

| Type | Double Acting & Single Acting (Spring Return) |

| Structure Features | Two-piece cylinder, high torque output, smooth and balanced operation; piston rod hard-chrome plated for wear resistance; sliding components with oil-free guide shafts and rings to reduce friction and extend service life |

| Applicable Valves | Large-diameter ball valves, butterfly valves, and other rotary valves |

| Torque Range | Double Acting: 515 – 157,300 Nm Single Acting: 230 – 37,000 Nm |

| Cylinder Volume | 3.25 L – 315 L |

| Functions | Double Acting: Two-position control for valve open/close Spring Return: Automatic open/close when power or air supply fails Single Solenoid Valve: Valve opens or closes when powered, opposite when unpowered (Explosion-proof optional) Double Solenoid Valve: One coil powers valve open, the other powers valve close, with memory function (Explosion-proof optional) Limit Switch Feedback: Remote signal for valve position (Explosion-proof optional) Electric Positioner: Controls valve flow based on 4~20mA signal Pneumatic Positioner: Controls valve flow based on 0.02~0.1MPa pressure signal I/P Converter: Converts electric signal to pneumatic, used with pneumatic positioner (Explosion-proof optional) |

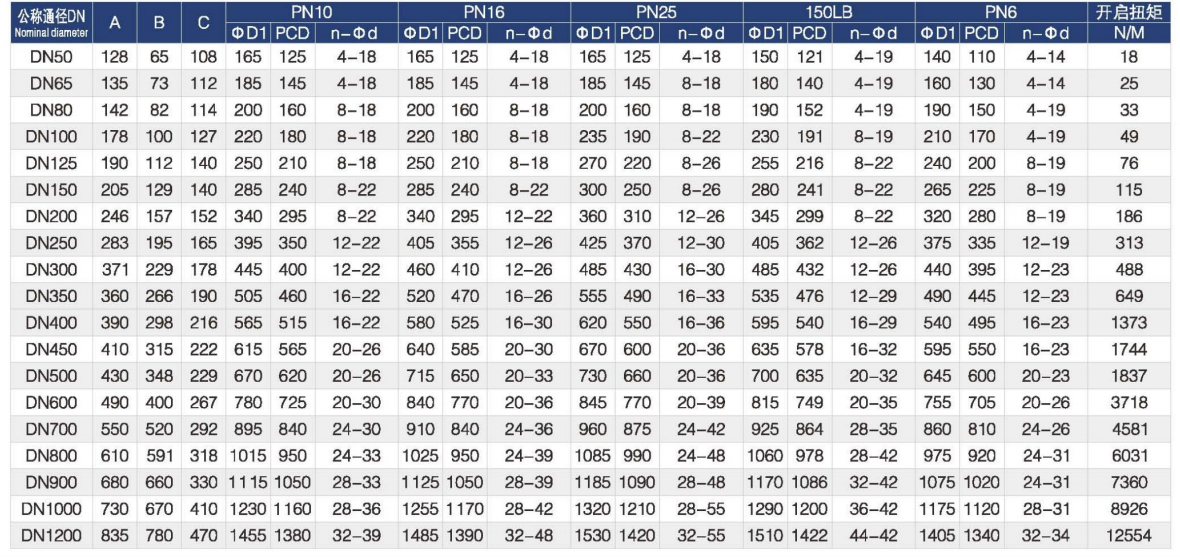

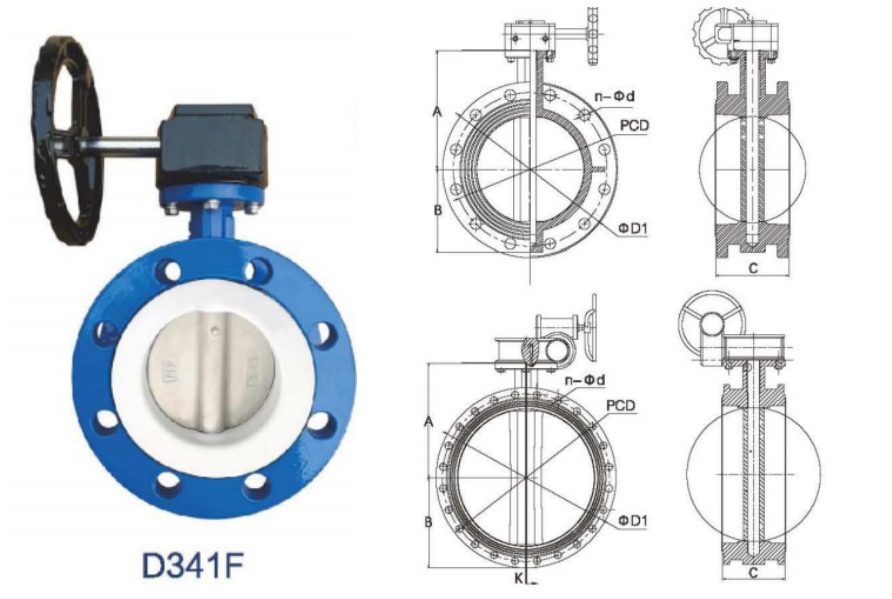

FAW-D-PF AW Pneumatic PTFE Fluorine Lining Butterfly Valve Structure and Dimension

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures