FAW-Q Pneumatic AW Trunnion Mounted Ball Valve

The Pneumatic AW Trunnion Mounted Ball Valve uses a trunnion-supported ball and air actuator to reduce torque and prevent leakage, ensuring stable flow control in high-pressure pipelines with API 6D and ISO 5211 certified reliability.

Technical Specifications

| Size Range | DN 50 – DN 600 (2″ – 24″) |

| Working Pressure Range: | Class 150 – Class 2500 / PN 16 – PN 420 |

| Working Temperature Range: | -29°C to +425°C |

| Body Material: | Carbon Steel (A105) / Stainless Steel (304, 316, 316L, CF8M) |

| Connection Type: | Flanged (ASME B16.5 / DIN / JIS) |

| Applicable Medium: | Oil, Gas, Water, Steam, Corrosive Liquids |

| Actuator Type: | Pneumatic AW Double-Acting or Spring-Return |

| Voltage Options | 24V DC / 110V AC / 220V AC |

| Design Standard | API 6D / ASME B16.34 / ISO 5211 |

| Testing Standard | API 598 / EN 12266-1 / ISO 5208 |

| Fire-Safe Design | API 607 / API 6FA |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

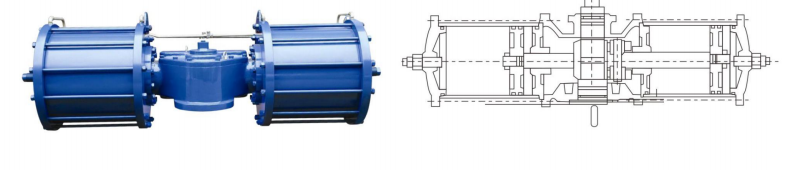

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Performance & Reliability

• Pneumatic AW Trunnion Mounted Ball Valve provides stable torque and zero leakage in high-pressure systems.

• Trunnion-supported ball design reduces seat wear and ensures long service life.

• Air-operated actuator offers precise control and consistent operation.

• API 6D-tested structure guarantees reliable sealing and performance stability.

2. Efficiency & Automation

• Pneumatic actuated ball valve enables fast opening and closing for efficient flow control.

• ISO 5211 mounting pad supports direct connection with solenoid valves and positioners.

• Double-acting or spring-return actuator ensures fail-safe automation.

• Low-friction design improves response speed and reduces energy consumption.

3. Material & Application Flexibility

• Stainless steel, carbon steel, and alloy body options provide corrosion and pressure resistance.

• Fire-safe construction fits oil, gas, and chemical environments.

• PTFE, PEEK, or metal seats handle abrasive or high-temperature media.

• Industrial trunnion ball valve covers wide pressure and temperature ranges.

4. Compliance & Maintenance Advantage

• Certified with CE, ISO 9001, ATEX, SIL 3, TÜV for global use.

• Modular pneumatic actuator simplifies maintenance and replacement.

• Split-body design allows quick inspection and seat renewal.

• Built to API 6D, ASME B16.34, EN 12266-1 for safety and reliability.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What makes the Pneumatic AW Trunnion Mounted Ball Valve ideal for high-pressure and industrial automation systems?

• Pneumatic trunnion-type valve ensures stable torque and zero leakage under extreme pressure.

• Air-driven actuator enables fast and precise flow control for automated operations.

• Double-sealing structure provides reliable shut-off in both high and low pressure conditions.

• Built to API 6D and ISO 5211 standards for dependable industrial performance.

2. How can the Pneumatic AW Trunnion Mounted Ball Valve be integrated into automated control systems?

• Pneumatic actuator ball valve connects directly through ISO 5211 mounting pad.

• Double-acting or spring-return actuator offers fail-safe automation.

• Compatible with PLC and DCS systems for remote operation and feedback.

• Modular actuator design enhances efficiency and simplifies upgrades.

3. What types of media and industries best suit the Pneumatic AW Trunnion Mounted Ball Valve?

• Actuated trunnion ball valve handles oil, gas, steam, and corrosive fluids with durable steel construction.

• Fire-safe and anti-static design ensures safety in petrochemical and power industries.

• PTFE, PEEK, or metal seats adapt to abrasive or high-temperature conditions.

• Suitable for pipeline automation valves across upstream and downstream sectors.

4. How do you maintain and extend the service life of a Pneumatic AW Trunnion Mounted Ball Valve?

• Split-body design allows easy seat and seal replacement without removing the valve from the line.

• Routine inspection of the air-operated actuator maintains stability and leak-free operation.

• Clean, dry air supply prevents corrosion and actuator failure.

• Regular testing ensures compliance with API 598 for sealing integrity.

5. What is the difference between a Pneumatic AW Trunnion Mounted Ball Valve and a floating-ball valve?

• Pneumatic trunnion-mounted valve supports the ball on two points for reduced torque and wear.

• Floating-ball valve relies on downstream pressure, suitable for smaller or lower-pressure systems.

• Trunnion configuration offers smoother actuation and enhanced sealing stability.

• Air-actuated trunnion valve performs better in large-bore, high-pressure, and automated systems.