FAT-Q-3S Pneumatic 3-Way Tri-Clamp Sanitary Ball Valve

The Pneumatic 3-Way Tri-Clamp Sanitary Ball Valve features a 316L stainless steel polished body and pneumatic actuation for precise T/L-port flow control, enhancing hygiene and efficiency; its full-bore design minimizes residue, shortens cleaning by 40%, and ensures leak-free performance per EN 12266-1 / API 598.

Technical Specifications

| Size Range | 1/2″ – 4″ (DN15 – DN100) |

| Working Pressure Range: | 0 – 10 bar (0 – 145 psi) |

| Working Temperature Range: | -20°C to +180°C |

| Body Material: | SS304 / SS316L Stainless Steel |

| Connection Type: | Tri-Clamp / Sanitary Clamp |

| Applicable Medium: | Food, Beverage, Dairy, Pharmaceutical, Chemical Liquid |

| Actuator Type: | Double Acting or Spring Return Pneumatic Actuator |

| Voltage Options | 24V DC / 110V AC / 220V AC |

| Design Standard | ISO 5211, DIN 11850, 3A Sanitary Standard |

| Testing Standard | EN 12266-1 / API 598 |

| Fire-Safe Design | Not Required (Sanitary Application) |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

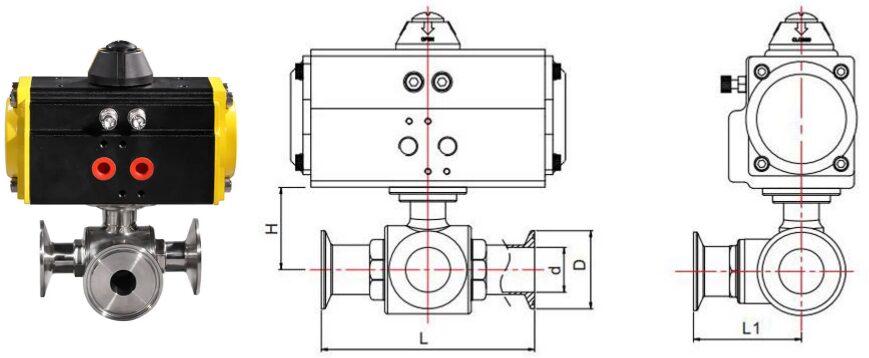

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Hygienic Design & Cleanability

• Pneumatic 3-Way Tri-Clamp Sanitary Ball Valve with 316L stainless steel body and polished surface ensures hygienic, bacteria-free flow.

• Tri-clamp connection allows quick installation and CIP/SIP cleaning for sanitary systems.

• Full-port flow path eliminates residue, ensuring efficient fluid transfer.

• FDA-approved PTFE seals provide chemical resistance and leak-free performance.

2. Flow Control & Operational Efficiency

• 3-way pneumatic ball valve with T/L port design offers precise flow diversion and mixing control.

• Air-actuated mechanism ensures fast response and stable automation.

• Compact design saves space while maintaining full-flow capacity.

• Pneumatic actuator supports double-acting or spring-return operation.

3. Durability & Reliability

• Stainless steel 316L construction resists corrosion in food and pharmaceutical environments.

• Reinforced PTFE seats ensure tight sealing and long service life.

• Each tri-clamp valve is pressure-tested per EN 12266-1 / API 598 standards.

• ISO 5211 mounting pad allows easy actuator replacement and integration.

4. Compliance & Application Versatility

• Certified with 3-A Sanitary, CE, RoHS, ISO 9001 standards.

• Ideal for food, beverage, dairy, pharmaceutical, and chemical process lines.

• Compatible with 24V DC, 110V AC, 220V AC control voltages.

• Air-operated 3-way clamp valve ensures safe, sterile flow control in aseptic systems.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What is the correct cleaning protocol for a pneumatic 3-way sanitary tri-clamp ball valve used in food and beverage lines?

• Apply a sanitary tri-clamp ball valve cleaning method for hot or cold CIP cycles to maintain hygiene.

• Flush the valve body and cycle the flow path to remove residue and prevent buildup.

• Ensure PTFE gaskets and seals are compatible with cleaning chemicals and sterilization temperature.

• Verify the three-way ball valve tri-clamp configuration maintains zero leakage after cleaning.

2. How can I integrate a three-way tri-clamp sanitary ball valve with pneumatic actuation into my automation system?

• Use an ISO 5211 interface for direct mounting of a pneumatic actuator.

• Match actuator air pressure and control voltage with your automation system for stable operation.

• Configure T-port or L-port settings for precise flow diversion with the air-actuated sanitary valve.

• Test actuator response, feedback signal, and cycle performance before commissioning.

3. What factors impact the lifespan and sanitary performance of a tri-clamp three-way pneumatic ball valve?

• Choose 316L stainless steel and polished interiors to prevent microbial adhesion.

• Use reinforced PTFE seats for high-cycle sealing and extended service life.

• Operate within rated limits of pressure and temperature to prevent stress or leakage.

• Schedule regular inspection of actuator linkage and clamp joints to maintain reliability.

4. Which installation steps are essential when specifying a tri-clamp sanitary 3-way ball valve for aseptic processing?

• Align clamp ferrules and tighten evenly to ensure a secure seal.

• Maintain adequate clearance around the actuator and clean air supply for smooth operation.

• Select T-port or L-port orientation according to your system’s flow direction.

• Pressure test the sanitary tri-clamp pneumatic valve and confirm zero leakage before startup.

5. How do I determine if a three-way tri-clamp pneumatic sanitary ball valve fits my process application?

• Ensure compliance with 3A, FDA, CE, and ISO 9001 standards for hygienic systems.

• Match tri-clamp dimensions to existing pipelines for quick integration.

• Verify actuator voltage options such as 24 V DC, 110 V AC, or 220 V AC for automation compatibility.

• Choose between T-port and L-port flow patterns to suit mixing or diversion processes.