FAT-Q-TF 3 Way Flange Stainless Steel Ball Valve

The 3 Way Flange Stainless Steel Ball Valve uses a CF8M body and PTFE seats for corrosion resistance and tight sealing, offers precise flow diversion or mixing with a pneumatic actuator, and is proven by 100,000-cycle durability tests under PN63 pressure and 180 °C.

Technical Specifications

| Size Range | DN15 – DN200 (1/2″ – 8″) |

| Working Pressure Range: | PN16 – PN63 (Class 150 – 600) |

| Working Temperature Range: | -20°C to +180°C |

| Body Material: | CF8 / CF8M (Stainless Steel 304 / 316) |

| Connection Type: | Flanged Ends |

| Applicable Medium: | Water, Air, Steam, Oil, Gas, Acid, Alkali, Corrosive Fluids |

| Actuator Type: | Pneumatic Rack & Pinion Actuator |

| Voltage Options | 24V DC, 110V AC, 220V AC |

| Design Standard | ISO 5211, ASME B16.34, API 6D |

| Testing Standard | API 598 / EN 12266-1 |

| Fire-Safe Design | Optional per API 607 / ISO 10497 |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

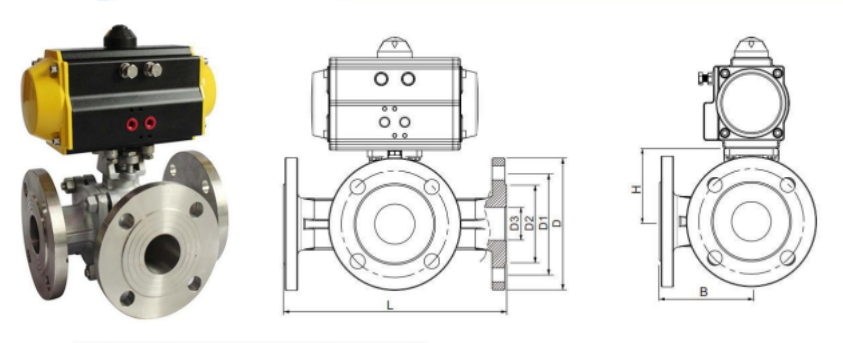

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Precision Flow Control & Operation

• 3 Way Flange Stainless Steel Ball Valve provides precise flow diversion and mixing control for automated pipelines.

• Full-port stainless steel body ensures low pressure loss and stable fluid flow.

• Pneumatic actuator delivers fast torque and reliable operation under high pressure.

• Supports positioner and feedback system for accurate valve automation.

2. Durability & Corrosion Resistance

• CF8/CF8M stainless steel body resists corrosion in chemical and marine conditions.

• PTFE or RPTFE seats ensure tight sealing under high temperature and pressure.

• Optional fire-safe design per API and ISO standards for enhanced safety.

• Precision-machined sealing surfaces extend service life and prevent leakage.

3. Maintenance & Installation Efficiency

• ISO 5211 mounting pad allows quick actuator installation.

• Flanged end connections (ANSI/DIN/JIS) simplify pipeline assembly.

• Blow-out-proof stem ensures safe continuous operation.

• Modular body enables easy seat and seal replacement.

4. Industry Versatility & Application Adaptability

• Suitable for chemical processing, water treatment, and oil & gas systems.

• Handles acid, gas, steam, and slurry with reliable sealing performance.

• Available with pneumatic or air-operated actuator configurations.

• Certified CE, ISO 9001, ATEX, meeting global industrial standards.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What are the key advantages of using a 3 Way Flange Stainless Steel Ball Valve in automated flow systems?

• Three-port stainless ball valve enables precise flow diversion and mixing in complex pipelines.

• Flanged stainless valve minimizes pressure loss and simplifies system layout.

• Pneumatic actuator ensures fast torque response and stable automation.

• 316 stainless steel body provides strong corrosion resistance and long service life.

2. How do I choose between an L-port and T-port configuration for a three-way stainless flanged valve?

• L-port valve is ideal for diverting flow between two lines without mixing.

• T-port design supports mixing or simultaneous flow for blending processes.

• Match the pneumatic actuator type with the required flow direction for smooth control.

• Ensure flanged connections meet ANSI, DIN, or JIS standards for reliable sealing.

3. Can a 3 Way Stainless Flanged Ball Valve handle aggressive chemicals and high-temperature media?

• CF8M stainless valve with PTFE or RPTFE seats resists corrosion and high temperatures up to +180 °C.

• Fire-safe structure ensures safety under extreme heat or flammable media.

• Steel construction maintains sealing integrity in steam and gas systems.

• Confirm pressure class and actuator compatibility with the operating environment.

4. What are the most common installation mistakes to avoid with a three-port flanged steel valve?

• Choosing the wrong L or T flow path may cause unwanted bypass or mixing.

• Incorrect pressure class or flange size leads to misalignment and leaks.

• Poor actuator alignment or missing ISO 5211 mounting reduces accuracy.

• Using low-grade materials instead of stainless steel and Teflon seats shortens valve life.

5.What seat materials and temperature limits apply to a flanged stainless three-way valve?

• Standard PTFE or RTFE seats suit most chemicals and temperatures from -20 °C to 180 °C.

• For higher heat or abrasive media, use filled PTFE or PEEK seats.

• Ensure body (316 SS or CF8M) and seat selection align with medium, pressure, and cleaning requirements.