FAT-Q-F Pneumatic Carbon Steel Fluorine Lining Ball Valve

The Pneumatic Carbon Steel Fluorine Lining Ball Valve with PTFE/PFA lining offers strong acid and alkali resistance, ensuring reliable sealing and long service life in corrosive pipelines, verified by API 598 and GB 13927 pressure tests for proven durability and stability.

Technical Specifications

| Size Range | DN15–DN300 (1/2″–12″) |

| Working Pressure Range: | PN10–PN16 (10–16 bar) |

| Working Temperature Range: | −20°C to +180°C |

| Body Material: | Carbon Steel (WCB) with PTFE/PFA Lining |

| Connection Type: | Flanged Ends (DIN, ANSI, JIS) |

| Applicable Medium: | Acid, Alkali, Salt, Corrosive Chemicals |

| Actuator Type: | Pneumatic Actuator (Double-Acting/Spring-Return) |

| Voltage Options | 24V DC, 110V AC, 220V AC |

| Design Standard | GB/T 12237, ISO 5211, API 608 |

| Testing Standard | GB/T 13927, API 598 |

| Fire-Safe Design | Optional |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

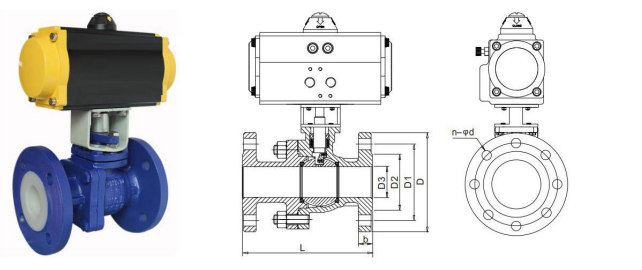

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Corrosion Resistance & Material Protection

• Pneumatic Carbon Steel Fluorine Lining Ball Valve with PTFE/PFA lining resists strong acid and alkali corrosion.

• Fluoropolymer-lined ball valve ensures chemical purity for chemical and pharmaceutical use.

• Smooth lining prevents scaling and maintains stable flow.

• High resistance to chlorine, hydrochloric acid, and corrosive solvents.

2. Pneumatic Automation & Control Precision

• Air operated fluorine lined valve offers fast actuation and reliable automation.

• Double-acting or spring-return design enhances safety.

• PTFE lined control valve supports precise remote control via solenoid and limit switch.

• ISO 5211 interface enables easy actuator installation.

3. Sealing Integrity & Performance Stability

• PTFE/PFA lined pneumatic ball valve provides zero leakage and tight sealing.

• Blowout-proof stem ensures operation under pressure.

• Full-port design reduces pressure drop and saves energy.

• Tested to API 598 and GB/T 13927 standards for sealing reliability.

4. Industrial Application Versatility

• Fluorine lined pneumatic valve fits chemical, petrochemical, and wastewater systems.

• Handles acids, alkalis, and oxidizing fluids in process control.

• Supports PLC or DCS automation systems.

• Long service life, low maintenance, and corrosion resistance.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. How does the fluorine lining in a fluorine lined ball valve for corrosive services extend equipment life in harsh chemical environments?

• The PTFE/PFA lining isolates the metal body from corrosive media, preventing acid and alkali damage.

• The non-stick surface minimizes deposits, ensuring smooth fluid flow.

• The fluoropolymer layer maintains purity in chemical and pharmaceutical pipelines.

• Reduced corrosion means fewer shutdowns and longer service life.

2. What are key considerations when deploying a pneumatic actuated fluorine lining ball valve in automated systems?

• Confirm ISO 5211 actuator compatibility for seamless pneumatic control.

• Match valve bore and flow capacity to system pressure and process needs.

• Keep temperature and pressure within rated limits to protect the lining.

• Use compatible solenoid valves and positioners for precise automation.

3. In which applications does a carbon steel body fluorine-lined ball valve for chemical pipelines outperform standard valves?

• Ideal for strong acid, alkali, and solvent transfer lines.

• Ensures chemical purity and zero contamination in process systems.

• Reduces maintenance in aggressive fluid environments.

• Enhances automation efficiency with reliable pneumatic actuation.

4. What operational practices help maximize the lifespan of a PTFE lined pneumatic ball valve in corrosive service?

• Operate strictly within temperature and pressure limits.

• Avoid sudden pressure surges and thermal shocks.

• Inspect and clean regularly to prevent abrasive wear.

• Maintain stable air supply and actuator torque balance.

5. How does a fluoropolymer lined ball valve with pneumatic actuation compare to conventional metal ball valves in corrosive environments?

• Offers superior resistance to chemicals and oxidizing fluids.

• Reduces maintenance costs and downtime versus unlined metal valves.

• Ensures tight sealing for hazardous media handling.

• Provides longer operational life and better value in corrosive systems.