FLE-D-SS Electric Sanitary Quick-Clamp Butterfly Valves

The Electric Sanitary Quick-Clamp Butterfly Valve features a 316L stainless-steel body and tri-clamp design, ensuring quick cleaning, easy maintenance, and precise control, backed by CE, FDA, RoHS, and EN 12266-1 certification.

Technical Specifications

| Size Range | DN25–DN150 (1″–6″) |

| Working Pressure Range: | 0–10 bar (0–145 psi) |

| Working Temperature Range: | -10°C to +120°C |

| Body Material: | AISI 304 / AISI 316L Stainless Steel |

| Connection Type: | Tri-Clamp / Quick-Clamp |

| Applicable Medium: | Food, Beverage, Dairy, Pharmaceutical, Water |

| Actuator Type: | Electric Rotary Actuator |

| Voltage Options | AC220V, AC110V, DC24V |

| Design Standard | ISO 5211, DIN 11850, 3A, ASME BPE |

| Testing Standard | EN 12266-1, ISO 9001 |

| Fire-Safe Design | Not Applicable |

| Certification | CE / ROHS / ISO / SIL / TUV /IP68 Waterproof |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

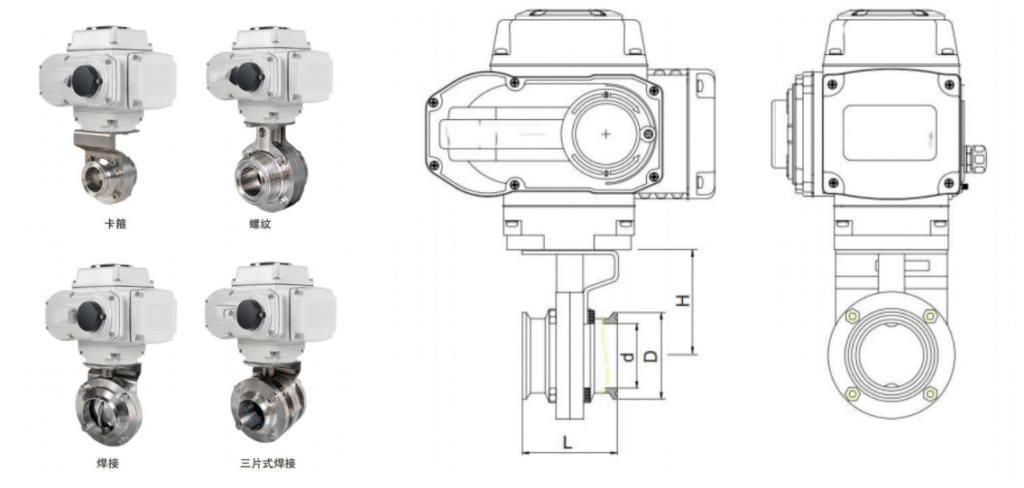

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Hygienic Design & Compliance

• Electric Sanitary Quick-Clamp Butterfly Valve with 316L stainless steel polished body meets 3A sanitary and ASME BPE standards.

• Tri-clamp connection enables fast cleaning and easy disassembly for CIP/SIP systems.

• Smooth flow path prevents residue and ensures purity in food and beverage processing.

• Certified by FDA, CE, RoHS, suitable for dairy, pharmaceutical, and bioprocessing applications.

2. Precision Automation & Control

• High-torque electric actuator provides precise on/off and modulating control.

• Supports AC220V, AC110V, DC24V for industrial automation systems.

• Low-noise, stable operation ensures consistent performance.

• Optional IP68 waterproof actuator for washdown and humid environments.

3. Durability & Performance

• Corrosion-resistant stainless steel with EPDM or PTFE seat ensures long sealing life.

• Tested under EN 12266-1 and ISO 9001 for leak-free operation.

• Compact body handles up to 10 bar pressure for reliable flow control.

• Optional graphite sealing improves high-temperature and wear resistance.

4. Efficiency & Cost Optimization

• Quick-clamp design allows tool-free maintenance and reduces downtime.

• Low flow resistance improves energy efficiency in automated lines.

• Electric control valve saves energy versus pneumatic systems.

• Reliable sealing reduces product waste and boosts production efficiency.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What makes the Electric Sanitary Quick-Clamp Butterfly Valve ideal for hygienic food and beverage systems?

• 316L stainless-steel polished body meets 3A and ASME BPE standards for clean applications.

• Tri-clamp connection enables fast installation and CIP/SIP cleaning.

• Smooth interior prevents residue and ensures purity in dairy, brewing, and pharmaceutical systems.

• Certified with FDA, CE, and RoHS for global hygienic flow control.

2. How to choose the correct size and pressure rating for an Electric Hygienic Butterfly Valve installation?

• Match the valve diameter to the process line for minimal pressure loss.

• Most quick-clamp butterfly valves operate up to 10 bar (145 psi).

• Check fluid viscosity and actuator torque for reliable automation.

• Use EN 12266-1 tested valves for consistent performance.

3. How to maintain an Electric Tri-Clamp Butterfly Valve for long-term reliability?

• Inspect EPDM or PTFE seats regularly to prevent leakage.

• Keep clamp connections clean to avoid bacterial buildup.

• Ensure IP68 actuator housing stays dry during wash-down.

• Replace seals periodically to maintain food-grade performance.

4. What factors determine the actuator reliability of an Electric Actuated Sanitary Butterfly Valve?

• Choose multi-voltage actuators (AC220V, AC110V, DC24V) for system compatibility.

• Use IP67/IP68 waterproof actuators in humid environments.

• Match torque rating to valve size and pressure.

• Ensure ISO 5211 mounting pad fits automation standards.

5. What certifications should a Sanitary Electric Butterfly Valve carry for global compliance?

• Include 3A, FDA, and ASME BPE for sanitary use.

• Add CE, RoHS, and TÜV for electrical safety and exports.

• Maintain ISO 9001 and EN 12266-1 for leak testing.

• Optional SIL and IP68 ratings enhance safety and reliability.