FLE-D-CEF Intelligent Electric Cast Iron Flanged EPDM Butterfly Valves

The Electric Cast Iron Flanged EPDM Butterfly Valve features a durable cast iron body, EPDM seat, and electric actuator for precise flow control and tight sealing under PN10/PN16 pressure, ensuring reduced leakage, lower maintenance, and verified reliability through CE and ISO 9001 standards.

Technical Specifications

| Size Range | DN50–DN600 (2″–24″) |

| Working Pressure Range: | PN10 / PN16 (10–16 bar) |

| Working Temperature Range: | -10°C to +120°C |

| Body Material: | Cast Iron |

| Connection Type: | Flanged End |

| Applicable Medium: | Water, Air, Steam, Weak Acids, Weak Alkalis |

| Actuator Type: | Electric Quarter-Turn Actuator |

| Voltage Options | AC110V / AC220V / AC380V / DC24V |

| Design Standard | EN593 / API 609 / ISO 5211 |

| Testing Standard | API 598 / EN 12266-1 |

| Fire-Safe Design | Optional per API 607 |

| Certification | CE / ROHS / ISO / SIL / TUV /IP68 Waterproof |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

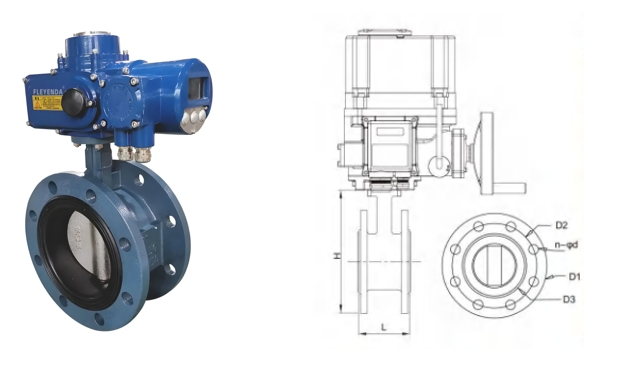

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Reliable Flow Control & Sealing Performance

• The Electric Cast Iron Flanged EPDM Butterfly Valve provides accurate flow regulation and secure shutoff for water, air, and chemical pipelines.

• Electric actuator ensures stable operation and precise control under PN10/PN16 pressure.

• EPDM seat offers tight sealing and leak-free performance.

• Optimized disc design reduces friction and improves reliability.

2. Durability & Material Strength

• Cast iron body provides high strength for industrial use.

• Stainless steel disc and stem resist corrosion and pressure impact.

• EPDM liner maintains sealing flexibility across temperature changes.

• Coated surface protects the electric actuated valve from rust and wear.

3. Easy Automation & Installation Flexibility

• Flanged connection allows quick, accurate pipeline installation.

• ISO 5211 mounting pad supports multiple actuator types.

• Wide voltage range (AC/DC) fits various automation systems.

• Compact structure suits HVAC, water treatment, and industrial flow control.

4. Safety Assurance & International Compliance

• Tested per API 598 and EN 12266 for leak-tight performance.

• Optional fire-safe design meets API 607 requirements.

• Certified with CE, RoHS, ISO 9001 for global reliability.

• Low-torque operation reduces actuator load and maintenance frequency.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What is the ideal application for the Electric Cast Iron Flanged EPDM Butterfly Valve in water systems?

• The Electric Cast Iron Flanged EPDM Butterfly Valve is suitable for water treatment and industrial water pipelines requiring precise shutoff and flow regulation.

• The EPDM liner provides strong chemical resistance and reliable sealing.

• The electric actuator enables automated control and remote operation.

• The flanged cast iron body ensures stable installation and leak-free performance.

2. How to size a motorized flanged butterfly valve for HVAC or process systems?

• Calculate flow rate and system pressure drop to determine the required torque for the motorized butterfly valve.

• Match the electric actuator torque to valve size for complete and reliable closure.

• Confirm flange standard (ANSI/DIN/JIS) and ensure pipe compatibility.

• Choose an EPDM-seated butterfly valve for chilled or hot water circulation.

3. What are the key installation precautions for an electric flanged butterfly valve in industrial pipelines?

• Clean the pipeline before installing the electric flanged valve to prevent EPDM seat damage.

• Tighten flange bolts evenly to maintain proper alignment and sealing.

• Mount the electric actuator correctly on the ISO 5211 pad and connect suitable voltage.

• Verify the EPDM seat is compatible with the working medium.

4. How to maintain an electric actuated EPDM butterfly valve for long service life?

• Operate the electric butterfly valve periodically to prevent actuator and seat sticking.

• Inspect the EPDM seat for hardening or cracking under temperature cycles.

• Recalibrate actuator limit switches for precise disc movement.

• Check flange bolts and alignment to preserve sealing integrity.

5. Can the electric cast iron flanged butterfly valve be used for throttling control?

• Yes, the electric butterfly valve supports modulating flow control with feedback-enabled actuators.

• The EPDM-lined design suits water, air, and light chemical media.

• Ensure both the cast iron body and actuator are rated for the required pressure and temperature.

• Select a valve size and flow coefficient that enable stable throttling control.