FLE-Q-PD Electric 3-Way UPVC Ball Valve

The Electric 3-Way UPVC Ball Valve combines a corrosion-resistant UPVC body and electric actuator for precise L- or T-port flow control, ensuring reliable chemical compatibility, leak-free operation, and long service life verified by CE, RoHS, and ISO9001 certifications.

Technical Specifications

| Size Range | DN15 – DN100 (1/2″ – 4″) |

| Working Pressure Range: | PN10 (≤1.0 MPa / 145 PSI) |

| Working Temperature Range: | 0°C to 60°C (32°F to 140°F) |

| Body Material: | UPVC |

| Connection Type: | Union Socket or Female Thread |

| Applicable Medium: | Water, Acid, Alkali, Salt Solution, Weak Chemical Liquids |

| Actuator Type: | Electric Quarter-Turn Actuator |

| Voltage Options | AC220V, AC110V, DC24V, DC12V |

| Design Standard | ISO 5211, DIN, JIS, ANSI |

| Testing Standard | ISO 9393, GB/T 17241.6, EN 12266-1 |

| Fire-Safe Design | Not Applicable |

| Certification | CE / ROHS / ISO / SIL / TUV /IP68 Waterproof |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

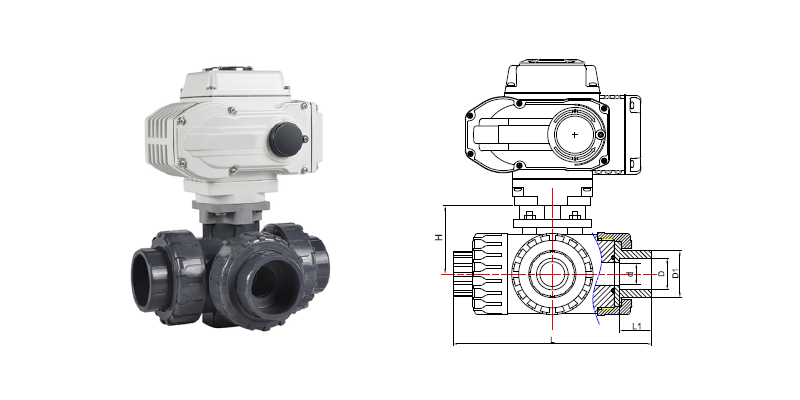

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Corrosion & Chemical Resistance

• The Electric 3-Way UPVC Ball Valve resists acids, alkalis, and solvents, ensuring durability in chemical and wastewater systems.

• UPVC body prevents rust and corrosion for stable, long-term performance.

• Smooth internal surface reduces scaling and maintains consistent flow.

• Suitable for aggressive media handling in industrial and water treatment pipelines.

2. Automation & Flow Control Flexibility

• Electric actuator enables remote automation and precise flow switching.

• L-port or T-port design supports easy diversion and mixing control.

• ON/OFF and modulating options ensure accurate flow regulation.

• Integrated feedback system improves control accuracy in automated processes.

3. Installation & Maintenance Efficiency

• Union-end connection allows quick installation and disassembly.

• Lightweight UPVC body simplifies handling and replacement.

• ISO 5211 mounting fits multiple electric actuators.

• Double O-ring sealing ensures leak-free performance.

4. Safety & Compliance Assurance

• Electrically insulated design enhances operational safety.

• IP67/IP68 waterproof actuator works reliably in humid or outdoor settings.

• Certified to CE, RoHS, and ISO9001 for international compliance.

• Non-flammable UPVC body ensures chemical and environmental safety.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What’s the difference between an L-port and T-port in an Electric 3-Way UPVC Ball Valve and how do I know which one to choose?

• The Electric 3-Way UPVC Ball Valve offers L-port for flow diversion and T-port for flow mixing or distribution.

• Choose an L-port when directing one inlet to two outlets; use a T-port for blending or splitting flow.

• T-port types are preferred in chemical and water systems for smoother flow control.

• Confirm actuator position settings before installation to ensure correct flow direction.

2. How can I install an Electric 3-Way UPVC Ball Valve to prevent leaks and electrical issues?

• Flush pipelines to remove debris and protect the UPVC seats from damage.

• Verify actuator voltage compatibility and secure wiring according to IP67/IP68 protection.

• Hand-tighten unions before applying torque to avoid cracking the valve body.

• Perform pressure and insulation tests to ensure sealing and electrical reliability.

3. Why is the Electric 3-Way UPVC Ball Valve popular in water treatment and chemical dosing systems?

• UPVC body resists acids, alkalis, and saltwater, ensuring long-term chemical compatibility.

• Electric actuation enables automatic flow switching without manual operation.

• Lightweight and corrosion-proof design reduces installation effort and maintenance.

• Proven to offer longer service life and lower failure rates in chemical environments.

4. What should I do if my Electric 3-Way UPVC Ball Valve stops switching or shows actuator errors?

• Disconnect power and check wiring and overload protection.

• Inspect limit switches and confirm alignment with the valve stem.

• Clean internal debris that may jam the UPVC ball or seals.

• Lubricate O-rings and seats regularly to restore smooth operation.

5. Can the Electric 3-Way UPVC Ball Valve be integrated into automated control systems?

• ISO 5211 mounting and multi-voltage actuators allow PLC or SCADA integration.

• Supports 4–20 mA or 0–10 V feedback for precise position monitoring.

• Automated valves improve batching accuracy and reduce operator error.

• Ensure proper grounding and surge protection in humid installations.