FLE-Q-F Fluorine Lining Motorized Ball Valve

Fleyenda FLE-Q-F Fluorine Lining Motorized Ball Valve is a two-way PTFE-lined valve built to GB, DIN, ANSI, and JIS standards. Its compact body design with minimal gaps reduces material buildup and crystallization, ensuring reliable sealing. Made with imported fluorine material and stainless or carbon steel body, it provides excellent corrosion and wear resistance. Suitable for highly corrosive media such as alkali salts, sulfuric acid, hydrofluoric acid, phosphoric acid, chlorine, and oxidative chemicals. Size range: 1/2”–4”, temperature -10°C to 180°C, operating pressure up to 16 bar.

Technical Specifications

| Size Range | DN15–DN300 (½”–12″) |

| Working Pressure Range: | PN10–PN16 (up to 1.6 MPa / 150 PSI) |

| Working Temperature Range: | –20 °C ~ +180 °C |

| Body Material: | Carbon Steel / Stainless Steel (WCB, CF8, CF8M) with PTFE or PFA lining |

| Connection Type: | Flanged (ANSI 150, DIN PN16, JIS 10K available) |

| Applicable Medium: | Strong acids, alkalis, chlorine, corrosive gas, organic solvents, and chemical wastewater |

| Actuator Type: | Electric actuator |

| Voltage Options | AC220V, AC110V, AC380V, DC24V |

| Design Standard | GB/T 12237, ISO 5211, ASME B16.34 |

| Testing Standard | GB/T 13927, API 598 |

| Fire-Safe Design | Optional (API 607 / ISO 10497 compliant versions available) |

| Certification | CE / ROHS / ISO / SIL / TUV /IP68 Waterproof |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

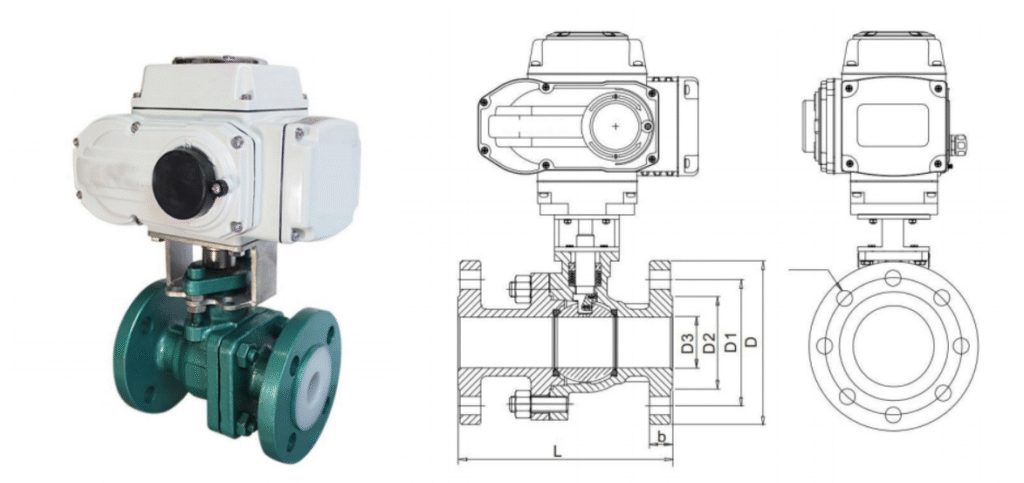

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Corrosion & Chemical Resistance

• Fluorine Lining Motorized Ball Valve with PTFE or PFA lining resists acids, alkalis, and chlorides.

• Corrosion-proof structure ensures reliable operation in chemical and wastewater systems.

• Delivers stable performance under long-term contact with aggressive media.

• Reduces maintenance frequency and extends service life.

2. Precision Control & Automation

• Motorized fluorine-lined ball valve provides accurate flow control with on/off or modulating actuation.

• Supports 4–20mA and 0–10V signals for seamless process automation.

• Stable torque ensures consistent sealing performance.

• Enables remote control, improving safety in corrosive environments.

3. Reliable Sealing & Leak Prevention

• Integrated fluoropolymer lining ensures zero leakage and strong sealing.

• Bubble-tight shutoff prevents cross-contamination.

• Sealing remains stable under temperature and chemical stress.

• Optional fire-safe and anti-static versions for hazardous use.

4. Durability & Application Flexibility

• Stainless steel or carbon steel body with PTFE lining provides mechanical strength.

• Electric fluorine lining ball valve supports ANSI, DIN, and JIS flanges.

• Compact design with AC220V, AC110V, or DC24V voltage options.

• Suitable for acid, alkali, chlorine, and chemical process control.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What are the real advantages of a Fluorine Lining Motorized Ball Valve in corrosive fluid systems?

• The Fluorine Lining Motorized Ball Valve uses PTFE or PFA materials that isolate corrosive media from metal surfaces, providing strong resistance to acids, alkalis, and chlorine-based compounds.

• The electric actuator enables precise remote operation, reducing manual contact with hazardous fluids and ensuring stable torque output.

• Compared with standard stainless valves, the fluorine-lined ball valve offers longer service life and reduced maintenance downtime, improving process efficiency.

2. How does the Fluorine Lining Motorized Ball Valve perform under temperature and pressure variations?

• A high-quality PTFE-lined motorized valve operates steadily up to about 120 °C and 16 bar, suitable for most chemical and wastewater systems.

• PFA-lined valves resist deformation during rapid heating or cooling cycles, maintaining consistent sealing.

• Matching media conditions with lining specifications prevents blistering or delamination, ensuring reliable long-term use.

3. Why do some motorized ball valves fail early in chemical service, and how can this be prevented?

• Common causes include misaligned installation, negative pressure, or abrasive particles damaging the fluorine lining.

• Correct flange alignment and proper wiring prevent actuator overload and leakage.

• Ensuring medium compatibility and correct torque settings significantly extends valve life and reliability.

4. How does a Fluorine Lining Motorized Ball Valve compare with solenoid valves in automation?

• The motorized ball valve provides full-port flow and tighter shutoff, ideal for corrosive or viscous fluids.

• The fluorine lining offers superior chemical resistance where solenoid valves would corrode quickly.

• Solenoid valves switch faster for light-duty use, while electric-actuated fluorine-lined valves perform better in heavy chemical or process control systems.

5. What maintenance ensures long-term reliability of a Fluorine Lining Motorized Ball Valve?

• Inspect actuator housing and flange joints regularly for leaks or discoloration.

• Cycle the valve periodically to prevent seat adhesion and maintain actuator performance.

• Record operating hours, media type, and temperature to predict maintenance needs.

• Use compatible gaskets to protect the PTFE-lined body from chemical attack.