FLE-VQ-F Motorized V-Port Segmented Ball Valve

Fleyenda FLE-VQ-F Motorized V-Port Segmented Ball Valves combine the accuracy of flow control with the durability of a ball valve design. Featuring integrated V-notch ports for enhanced flow characteristics, these valves minimize seat wear and deliver stable performance. Available with 15°, 30°, 60°, and 90° V-port options, they cover a wide control range from fine regulation to high Cv applications. Constructed from stainless steel 304/316/316L with PTFE sealing, sizes range from 1″ to 8″ (DN25–DN200). Operating pressure is 10–16 bar, with a temperature range of -10°C to 180°C, making them ideal for water, chemical, and industrial process control.

Technical Specifications

| Size Range | 1″ – 12″ (DN25 – DN300) |

| Working Pressure Range: | PN16 – PN40 / ANSI Class 150 – 300 |

| Working Temperature Range: | -20°C to +250°C (depending on seat material) |

| Body Material: | Stainless Steel CF8 / CF8M / Carbon Steel WCB |

| Connection Type: | Flanged (ANSI, DIN, JIS standards) |

| Applicable Medium: | Water, Steam, Gas, Oil, Slurry, Pulp, Chemical Liquids |

| Actuator Type: | Electric Motorized Actuator |

| Voltage Options | AC220V, AC110V, AC380V, DC24V |

| Design Standard | IEC 60534 / GB/T 12237 / API 6D |

| Testing Standard | API 598 / EN 12266-1 |

| Fire-Safe Design | Optional per API 607 Standard |

| Certification | CE / ROHS / ISO / SIL / TUV /IP68 Waterproof |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

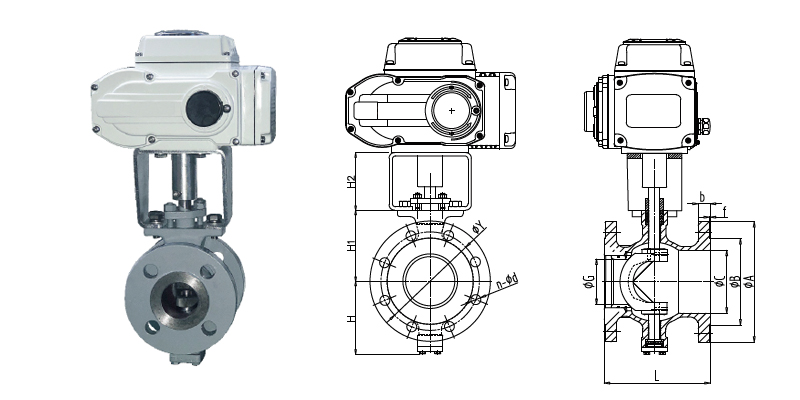

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Precision Flow Control & Smart Regulation

• Motorized V-port segmented ball valve provides accurate throttling for stable, repeatable flow control.

• V-shaped ball design ensures precise modulation of liquid, gas, or slurry in industrial automation.

• Equal-percentage flow curve maintains consistent response under varying process loads.

• Electric actuator feedback enables precise and energy-efficient valve positioning.

2. Durability & Safety

• Stainless or carbon steel body resists corrosion and handles high pressure and temperature.

• PTFE or metal seat provides tight sealing in abrasive or high-viscosity media.

• Fire-safe, anti-static design meets ISO and API safety standards.

• Tungsten-coated ball edge extends service life under abrasive flow.

3. Automation & Energy Efficiency

• Electric actuator supports multi-voltage control and Modbus or 4–20 mA signal integration.

• Works with SCADA and PLC systems for automated monitoring and control.

• Compact, lightweight structure simplifies installation and maintenance.

• Electric drive system cuts energy use and noise versus pneumatic types.

4. Maintenance & Cost Efficiency

• Self-cleaning V-port minimizes clogging in slurry or particulate fluids.

• Replaceable seats and long cycle life reduce downtime and maintenance cost.

• Low operating torque lowers actuator load and power consumption.

• Flanged or wafer connection offers broad system compatibility and quick installation.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What makes the Motorized V-Port Segmented Ball Valve different from a regular electric control valve?

• Unlike standard on/off electric ball valves, the Motorized V-Port Segmented Ball Valve offers precision flow modulation through its V-notch design for fine adjustment instead of full open/close.

• It delivers smoother process control in industrial automation systems where flow stability and repeatability are critical.

• The segmented ball reduces turbulence and cavitation, extending service life under high-pressure or variable-flow conditions.

• Commonly used in chemical dosing, steam, and slurry applications to enhance efficiency.

2. How does a Motorized V-Port Segmented Ball Valve improve flow control accuracy in automation systems?

• The V-shaped port geometry provides a near-linear flow curve for accurate proportional control even at small openings.

• Integrated with a smart electric actuator, it supports 4–20 mA or Modbus feedback for precise loop control.

• It minimizes overshoot and hysteresis, improving PID stability and process accuracy.

• Ideal for upgrading from pneumatic to fully motorized modulating valves in automated plants.

3. What are the ideal applications for a Motorized V-Port Segmented Ball Valve in modern industries?

• Common in HVAC, water treatment, pulp and paper, and chemical processing, where both precision and automation are needed.

• The segmented design handles liquids, gases, and slurries with minimal clogging and a self-cleaning shear action.

• High rangeability ensures accurate control from small to large flow volumes, optimizing energy use in process plants.

• Effective for temperature control loops and feed-flow regulation, often replacing globe valves.

4. What maintenance does a Motorized V-Port Segmented Ball Valve require for long-term performance?

• Inspect the V-notch surface and seat for wear from high-velocity or abrasive media.

• Check actuator alignment, torque, and feedback signals for accurate modulation.

• Lubricate moving parts and protect electrical connections from moisture or corrosion.

• Predictive maintenance through smart actuator diagnostics reduces downtime in continuous operations.

5. How should I choose the right Motorized V-Port Segmented Ball Valve for my application?

• Match the V-Port angle (30°, 60°, or 90°) to the required flow control precision.

• Select body materials such as stainless steel or CF8M based on medium temperature and corrosivity.

• Ensure actuator torque, power supply, and feedback type fit your industrial automation system.

• Confirm Cv and rangeability are correctly sized to balance efficiency and service life.