FLE-Q-F Electric 2 Way Flange Ball Valve

• Electric 2 Way Flange Ball Valve features a stainless-steel full-bore design with an ISO 5211 electric actuator, ensuring precise 0–90° control, zero leakage, and automation efficiency; tested to API 598 and API 607, it operates from –20 °C to 180 °C under PN40 pressure, guaranteeing long-term reliability and safety.

Technical Specifications

| Size Range (Nominal Diameter) | DN15 – DN300 (½″ – 12″) |

| Working Pressure Range: | PN16 – PN40 / ANSI 150 – 300 Class (1.6 – 4.0 MPa / 150–300 psi) |

| Working Temperature Range: | –20 °C to +180 °C |

| Body Material: | Stainless Steel 304 / 316 or Carbon Steel WCB |

| Connection Type: | Flanged (ANSI B16.5 / DIN PN16 / JIS 10K) |

| Applicable Medium: | Water, Oil, Air, Gas, Steam, Weak Acid & Alkali |

| Actuator Type: | Electric Actuator (On/Off or Modulating) |

| Voltage Options | AC 220 V, AC 110 V, DC 24 V, AC 380 V |

| Design Standard | API 6D / GB/T 12237 / ISO 5211 |

| Testing Standard | API 598 / GB/T 13927 |

| Fire-Safe Design | API 607 Certified (Optional) |

| Certification | CE / ROHS / ISO / SIL / TUV /IP68 Waterproof |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

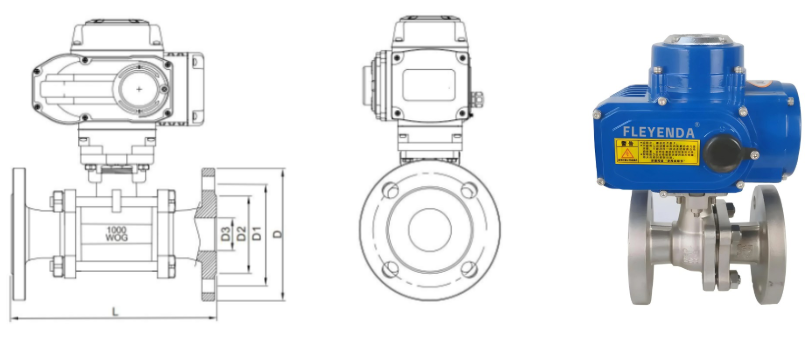

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Precision Flow Control & Automation Efficiency

• Electric actuator ensures accurate 0–90° rotation for reliable on/off or proportional flow regulation.

• Automated operation minimizes human error and allows remote or centralized process control.

• Fast response time improves system efficiency in industrial pipelines and HVAC applications.

• Supports integration with PLC or DCS systems for smart plant automation.

2. Durability & Leakage Prevention

• Full stainless-steel or WCB body resists corrosion, wear, and high pressure up to PN40.

• PTFE or RTFE seat design provides tight sealing to prevent internal and external leakage.

• Fire-safe and anti-static structure enhances safety in oil, gas, and chemical environments.

• Tested under API 598 and API 607 standards to ensure long-term reliability.

3. Installation & Maintenance Convenience

• Flanged connection (ANSI/DIN/JIS) allows easy alignment and secure bolting during installation.

• ISO 5211 mounting pad enables direct actuator replacement or upgrade without modification.

• Compact design saves space in complex piping systems.

• Low-torque operation reduces actuator wear and maintenance costs.

4. Broad Compatibility & Application Flexibility

• Suitable for water, air, oil, gas, steam, and weak acid/alkali media.

• Available in multiple voltages (AC 220 V, AC 110 V, DC 24 V, AC 380 V) for global compatibility.

• Operates reliably in temperature ranges from –20 °C to 180 °C.

• Certified to CE, ISO 9001, and API 607 standards for international compliance and safety.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What factors should I consider when selecting an Electric 2 Way Flange Ball Valve for automation?

• Match flange standard, size, and pressure rating (ANSI 150–300 / PN16–40) to avoid leakage and flow loss.

• Choose actuator mounting with ISO 5211 compatibility for easy integration.

• Ensure power compatibility (AC 220 V, DC 24 V, AC 110 V, AC 380 V).

• Verify material suitability (SS304/316 or WCB) for fluid type and temperature range.

2. How can I ensure reliable sealing and long service life?

• Select PTFE / RTFE seats with precision-machined stainless-steel ball for tight shut-off.

• Use API 607 fire-safe and anti-static design for chemical and gas industries.

• Confirm API 598 pressure and leakage tests for performance guarantee.

• Maintain periodic actuator torque and stem seal inspections.

3. Can the Electric 2 Way Flange Ball Valve be used for flow control instead of on/off?

• Yes, use a modulating actuator with feedback signal for precise throttling.

• Ensure valve design supports partial opening without seat damage.

• Apply V-port or characterised ball versions for linear flow control.

• Integrate with PLC / DCS system for automated regulation.

4. What are the key installation and wiring considerations?

• Align flange standards (ANSI / DIN / JIS) to prevent stress and leakage.

• Follow correct actuator wiring per voltage and control signal requirements.

• Provide mechanical support to avoid vibration damage to actuator.

• Calibrate open-close limits and test for zero-leak operation before

5. How can I verify product safety and certification compliance?

• Check CE, ISO 9001, and API 607 certificates for global approval.

• Confirm manufacturer testing under API 598 and API 6D standards.

• Ensure actuator IP67 / IP68 protection or explosion-proof options for harsh sites.

• Review technical data sheet for torque, temperature, and pressure limits.