FLE-Q-P Electric 2-Way UPVC Ball Valve

• Featuring a corrosion-resistant UPVC body and precision electric 2-way design, the FLE-Q-P Ball Valve ensures reliable flow control, minimizes leakage and downtime, and provides long-life performance proven in chemical, water, and automation systems.

Technical Specifications

| Size Range | Dn15 ~ Dn300 (½” ~ 12″) |

| Working Pressure Range: | Pn16 To Pn40 (16 To 40 Bar) |

| Working Temperature Range: | -20°C To 180°C |

| Body Material: | Stainless Steel 304、304L、316、316L |

| Connection Type: | Wafer |

| Applicable Medium: | Water, Oil, Gas, Steam, Corrosive & Non-Corrosive Chemicals |

| Actuator Type: | Electric Actuator (On/Off Or Modulating Control) |

| Voltage Options | 24V Dc, 110V Ac, 220V Ac, 380V Ac |

| Design Standard | Design Standard: Iso 5211, En 1092-1 (Flange Design) |

| Testing Standard | Api 598 (Valve Inspection And Testing) |

| Fire-Safe Design | Api 607 / Iso 10497 Certified (A Common And Critical Feature For This Valve Type) |

| Certification | Ce / Rohs / Iso / Sil / Tuv /Ip68 Waterproof |

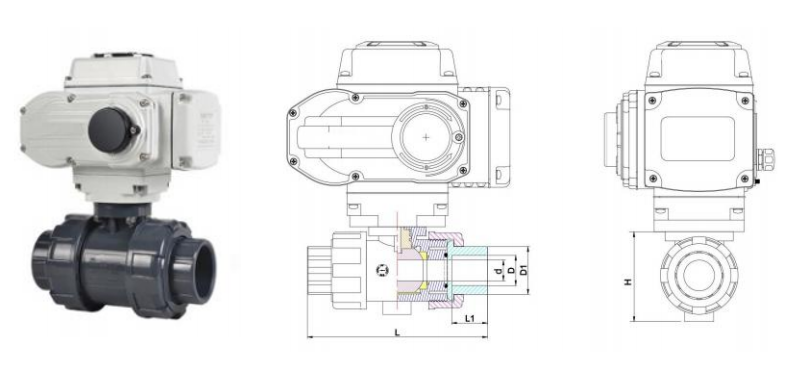

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Automation & Efficiency

• The FLE-Q-P Electric 2-Way UPVC Ball Valve enables precise flow control through electric actuation, ideal for water treatment and chemical processing systems.

• Fast quarter-turn operation ensures quick response and reduces system downtime.

• Low torque design minimizes actuator stress, extending service life and reducing maintenance frequency.

• Standard ISO 5211 mounting allows seamless integration with industrial automation systems and PLC control.

2. Corrosion & Chemical Resistance

• Constructed from high-grade UPVC, providing superior resistance to corrosion, rust, and aggressive chemicals.

• Suitable for applications handling acids, alkalis, salt solutions, and purified water.

• Non-metallic material prevents scaling and ensures clean media transport without contamination.

• Excellent chemical stability guarantees long-term performance in harsh industrial environments.

3. Reliability & Safety

• High-precision ball and seat design deliver reliable sealing and zero-leak performance.

• Electric actuation allows remote operation, improving workplace safety and operational convenience.

• IP67-rated actuator housing protects against dust and water ingress in demanding conditions.

• Consistent performance in continuous or automated systems ensures operational reliability and stability.

4. Cost & Installation Advantages

• Lightweight UPVC structure simplifies installation and reduces transportation costs.

• Lower power demand from reduced torque requirements minimizes energy consumption.

• Multiple connection options—socket, threaded, or flange adapters—enhance installation flexibility.

• Long service life, minimal maintenance, and reduced downtime contribute to lower total cost of ownership.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1.What is the maximum continuous temperature the FLE-Q-P Electric 2-Way UPVC Ball Valve can safely handle?

• The UPVC valve body typically handles continuous service up to around 60 °C (140 °F); above this range, the working pressure must be derated according to the manufacturer’s P/T chart.

• For higher-temperature service, consider CPVC or metal-body alternatives to avoid deformation or seal wear.

2.Is the FLE-Q-P Electric 2-Way UPVC Ball Valve suitable for potable water and chlorinated media?

• Yes—UPVC is inherently corrosion-resistant and non-toxic; select versions that meet NSF/ANSI 61 for drinking-water compliance.

• Ensure seals are EPDM or PTFE for compatibility with chlorinated water and sodium hypochlorite, and avoid solvent residues during installation.

3.What actuator protection rating and duty cycle are recommended for outdoor or wet-area installation?

• Choose an actuator enclosure rated IP67 for full dust protection and short-term immersion resistance.

• Confirm a 100% or 50% duty cycle rating if frequent open/close operations are expected, to prevent overheating of the motor.

4.How can I make the valve fail-safe (auto-close or auto-open) when power is lost?

• Select a spring-return or capacitor-stored fail-safe electric actuator, which automatically returns the valve to its default position (normally open or closed).

• Define the desired fail position and ensure torque margin is sufficient for sticky or viscous fluids.

5.Is an electric 2-way UPVC ball valve fast enough for surge or emergency shut-off applications?

• Electric actuators generally close more slowly than pneumatics (typically 5–15 seconds vs 1 second for pneumatics).

• If rapid shut-off is essential, add soft-close logic or consider a pneumatic actuator; otherwise, electric actuation provides smoother operation and longer component life.