FLE-Q-B Electric Italian Thin Type Wafer Ball Valve

• Compact design saves space and reduces installation time

• Low flow resistance improves efficiency and cuts energy use

• Durable materials ensure reliable performance in tough conditions

• Industry-certified for long-term reliability

Technical Specifications

| Size Range | Dn15 ~ Dn300 (½” ~ 12″) |

| Working Pressure Range: | Pn16 To Pn40 (16 To 40 Bar) |

| Working Temperature Range: | -20°C To 180°C |

| Body Material: | Stainless Steel 304、304L、316、316L |

| Connection Type: | Wafer |

| Applicable Medium: | Water, Oil, Gas, Steam, Corrosive & Non-Corrosive Chemicals |

| Actuator Type: | Electric Actuator (On/Off Or Modulating Control) |

| Voltage Options | 24V Dc, 110V Ac, 220V Ac, 380V Ac |

| Design Standard | Design Standard: Iso 5211, En 1092-1 (Flange Design) |

| Testing Standard | Api 598 (Valve Inspection And Testing) |

| Fire-Safe Design | Api 607 / Iso 10497 Certified (A Common And Critical Feature For This Valve Type) |

| Certification | Ce / Rohs / Iso / Sil / Tuv /Ip68 Waterproof |

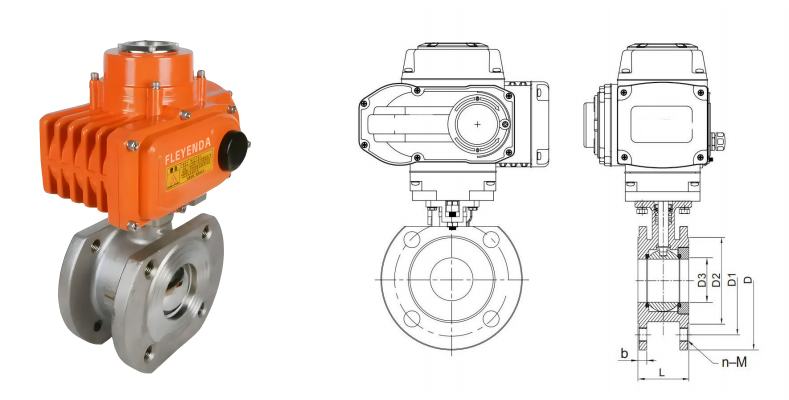

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

Compact & Easy Installation

•Ultra-Thin Wafer Profile: Saves significant space, ideal for compact pipe systems.

•Lightweight & Sturdy Body: Reduces structural load and simplifies handling.

•Wafer Type Design: Enables fast installation between flanges, lowering labor costs.

•ISO 5211 Mounting Pad: Allows for direct, tool-free actuator attachment.

Reliable Performance & Durability

•High Pressure & Temperature Rating: Handles up to PN40 and 180°C for demanding duties.

•Bubble-Tight Shut-Off: Ensures zero leakage, verified by API 598 standards.

•Corrosion-Resistant Materials: AISI 316 Stainless Steel body for long service life.

•Robust Construction: Built for reliable operation with water, oil, gas, and steam.

Automated Precision Control

•Electric Actuator Operation: Enables remote On/Off or modulating control.

•Multiple Voltage Options: 24V DC to 380V AC available for global compatibility.

•Fast Quarter-Turn Operation: Provides quick and precise flow control.

•Seamless System Integration: Ready for PLC and SCADA connectivity.

Safety & Certified Compliance

•API 607 Fire-Safe Design: Certified to prevent leakage in fire scenarios.

•International Certifications: Complies with CE and other key standards.

•Versatile Media Handling: Suitable for a wide range of aggressive and standard media.

•Safety-First Engineering: Ensures operational integrity in critical applications.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What are the primary advantages of using an Electric Italian Thin Type Wafer Ball Valve?

• Compact Design: Its slim profile allows for installation in tight spaces, making it ideal for applications where space is limited.

• Lightweight Construction: The valve’s lightweight nature simplifies handling and installation processes.

• Cost-Efficiency: The streamlined design reduces material usage, contributing to cost savings.

• Reliable Sealing: Equipped with an elastic sealing structure, it ensures a tight seal, preventing leaks and maintaining system integrity.

• Fire-Resistant Features: Incorporates fire-resistant structures to maintain functionality in case of fire, enhancing safety.

2. How does the electric actuator enhance the valve's performance?

• Automated Operation: Allows for remote control, reducing the need for manual intervention and improving operational efficiency.

• Precise Control: Facilitates accurate modulation of flow, ensuring optimal system performance.

• Safety Features: Many actuators include fail-safe mechanisms, such as spring return, to ensure the valve closes in the event of power loss.

• Feedback Signals: Some models offer feedback capabilities, providing real-time status updates to monitoring systems.

3. What materials are used in the construction of the valve, and how do they impact performance?

• Body and Ball: Stainless Steel 304/316/316L

• Sealing Material: PTFE (Polytetrafluoroethylene)

• Stem Material: Stainless Steel 304/316

These materials offer several advantages:

• Corrosion Resistance: Stainless steel provides excellent resistance to corrosion, ensuring longevity in various environments.

• Durability: The robust construction withstands high pressures and temperatures, enhancing the valve’s service life.

• Chemical Compatibility: PTFE seals are chemically inert, making the valve suitable for handling aggressive fluids.

4. Are there any maintenance requirements for the Electric Italian Thin Type Wafer Ball Valve?

Regular maintenance ensures optimal performance and longevity of the valve:

• Inspection: Regularly check for signs of wear, corrosion, or leakage.

• Cleaning: Keep the valve clean to prevent debris buildup, which can affect operation.

• Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear.

• Seal Replacement: Inspect and replace seals as needed to maintain a tight seal and prevent leaks.

5. What industries benefit most from using this type of valve?

The Electric Italian Thin Type Wafer Ball Valve is advantageous in various industries:

• Water Treatment: Efficient flow control in filtration and distribution systems.

• Chemical Processing: Handling aggressive chemicals with corrosion-resistant materials.

• HVAC Systems: Regulating heating and cooling fluids in compact mechanical rooms.

• Food and Beverage: Maintaining hygiene standards with easy-to-clean materials.

• Oil and Gas: Managing high-pressure fluids in pipelines.