F-ZSQP Piston Type Cut-off Valve

The Piston Type Cut-off Valve uses a precision piston actuator for accurate flow isolation and stable pressure control, ensuring zero leakage under high temperature and pressure, proven by API 598 and ISO 10497 test standards.

Technical Specifications

| Size Range | DN15–DN300 (½”–12″) |

| Working Pressure Range: | PN16–PN40 / ANSI 150–300LB |

| Working Temperature Range: | –20°C to +400°C |

| Body Material: | WCB / CF8 / CF8M / WC6 / WC9 |

| Connection Type: | Flanged (RF / FF / RTJ) |

| Applicable Medium: | Steam, Water, Air, Oil, Corrosive Fluids |

| Actuator Type: | Pneumatic Piston Actuator |

| Voltage Options | 24V DC / 110V AC / 220V AC |

| Design Standard | GB/T 12224 / ANSI B16.34 / IEC 60534 |

| Testing Standard | API 598 / EN 12266-1 / GB/T 13927 |

| Fire-Safe Design | API 607 / ISO 10497 |

| Certification | CE / RoHS / ISO 9001 / IP65 (Actuator) |

| Customization | Above Are Standard Parameter Samples. If You Have Specific Parameters And Materials, We Can Customize Them All. |

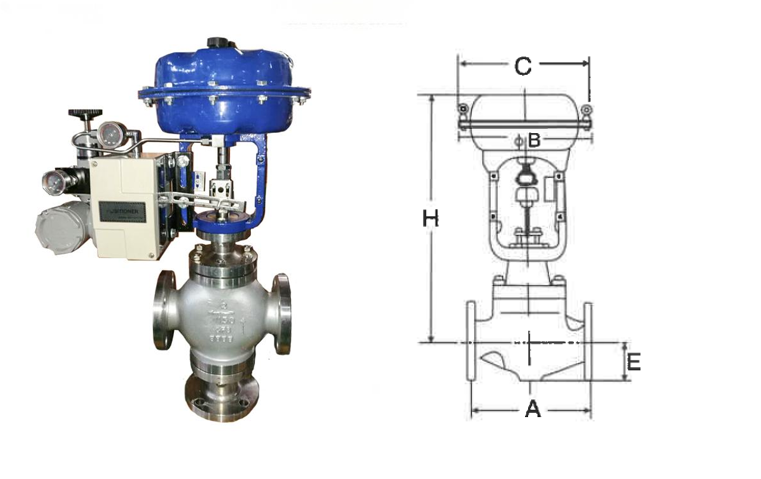

Product Drawings

Comprehensive Technical Drawing (Dimensions & Structure)

Product Benefits & Features

1. Precision Flow Control & Reliability

• The Piston Type Cut-off Valve ensures precise flow regulation and stable operation in industrial systems.

• Linear motion control delivers fast response and consistent pressure balance.

• The pneumatic piston actuator provides accurate throttling with minimal vibration.

• Optimized trim design achieves zero leakage and reliable shut-off.

2. Durability & Performance Under Extreme Conditions

• The industrial piston control valve uses WCB or stainless steel for corrosion and pressure resistance.

• PTFE or graphite seals maintain tight closure under steam, gas, and oil conditions.

• Fire-safe design certified by API 607 and ISO 10497 ensures safety in high-temperature environments.

• The pneumatic control valve offers long service life in chemical and refinery applications.

3. Energy Efficiency & Automation Compatibility

• The pneumatic piston-operated valve reduces air consumption and operating costs.

• Compatible with smart positioners for precise feedback and automatic control.

• Modular actuator design simplifies maintenance and replacement.

• Low-friction structure improves energy efficiency and actuator lifespan.

4. Safety, Compliance & Application Versatility

• The Piston Type Shut-off Valve meets CE, ISO9001, and SIL standards.

• Suitable for steam, air, water, and chemical flow control applications.

• Pressure-balanced design prevents unintentional actuation under variable load.

• Flanged RF/FF/RTJ connections enable easy installation in pipeline automation systems.

Why Choose Fleyenda Valve Manufacturing

Product Stability

We use reinforced structures and precision sealing to ensure consistent performance under pressure and temperature changes.

Conpany&Product Certification

We have CE, RoHS, ISO, SIL, TUV, and IP68 waterproof certifications covering safety, quality, and environmental standards.

Projects Experience

Cooperated over 40 countries, we have experience in oil & gas, energy, water, chemicals, food & beverage, and automation.

Customization Capability

With 20 years experience, we turn complex working conditions into precise valve solutions with high speed and accuracy.

Aftersales Support

•We have technical team provides real-time video support to help customers resolve on-site issues quickly.

Customer Cases

Trusted by Shell plc, Petronas, Chevron, TotalEnergies, and Dupont in projects across 40+ countries.

Our Product Actual Export Pictures

FAQs That 80% Users Interest

1. What makes the Piston Type Cut-off Valve more reliable than conventional shut-off valves in process control systems?

• The pneumatic piston shut-off valve ensures tight sealing and fast response under fluctuating pressure.

• Its linear motion design provides precise positioning and stable flow isolation.

• The PTFE-seated piston valve minimizes leakage and extends maintenance cycles.

• Suitable for oil, gas, steam, and chemical systems under high pressure and temperature.

2. How can I choose the right size and pressure rating for a Piston Actuated Control Valve in industrial pipelines?

• Determine maximum flow rate and differential pressure before sizing the industrial piston valve.

• Match the pressure class (PN16–PN40 / ANSI 150–300) to operating conditions.

• Select actuator and trim combinations that ensure accurate flow control without vibration.

• Use a modulating piston valve with high turndown ratio for variable load systems.

3. What maintenance practices improve the service life of a Pneumatic Piston Shut-off Valve in high-temperature or corrosive media?

• Choose corrosion-resistant materials such as stainless steel or alloy steel piston valves.

• Inspect seats and seals regularly to maintain zero-leak performance.

• Lubricate actuator parts and test pneumatic control response periodically.

• Replace worn piston guides or gaskets to ensure long-term sealing integrity.

4. Can the Piston Operated Shut-off Valve be integrated with automated plant control systems?

• Compatible with smart positioners and feedback for DCS or PLC integration.

• The pneumatic actuator valve supports fail-open or fail-close configurations.

• Enables predictive maintenance through digital control interfaces.

• Easily connects to automation pipelines using standard signal ranges.

5. In which applications is the Piston Type Shut-off Valve the best solution compared to other industrial valves?

• Ideal for steam isolation, chemical, and high-pressure oil and gas pipelines.

• Suitable for automated process systems requiring precise on-off control.

• Performs better than diaphragm or globe valves in fire-safe environments.

• Recommended for maintenance-friendly control systems with certified reliability.