Indonesia Paper Plant Valve Project

Project Background

An engineering company in Indonesia was developing a paper plant as part of a large-scale infrastructure project.

At the early construction stage, most facilities were still under planning, and the valve system specifications were incomplete.

When the client first contacted Fleyenda, they could only provide basic valve categories—such as ball valves and butterfly valves—without detailed parameters like materials, pressure ratings, sealing requirements, or connection types.

The initial quotation attempt was unsuccessful. However, through multiple rounds of technical discussions (over five to six iterations), the project gradually progressed as the client’s engineering team finalized the system requirements.

Key Challenges

This project presented exceptionally high complexity, mainly in three aspects:

1. Extremely Complex Valve Configuration

The final scope included:

-

873 valves in total

-

30+ valve types, including ball valves, butterfly valves, gate valves, and specialty valves

-

Over 100 size variations

-

Each valve had a unique Tag Number, for customers to identify

-

Even valves of the same type required different materials, trim configurations, sealing types, and connection standards

For example:

-

Butterfly valves varied by wafer, lug, and flanged connections

-

Different body materials, seat materials, and pressure classes were specified

-

Every valve parameter strictly matched its corresponding Tag Number

Tag Number

2. Customized PVDF Sealing Requirement

One of the most critical challenges was the PVDF sealing material.

-

PVDF sealing is not commonly used in the Chinese valve supply chain

-

The client specifically required PVDF due to chemical resistance requirements in paper handling

-

Fleyenda custom-developed and customized PVDF sealing solutions specifically for this project

This customization capability was a key factor in winning the client’s trust and differentiating Fleyenda from standard valve suppliers.

3. One-Stop Valve Procurement Solution

Although approximately 70% of the valves were manufactured by Fleyenda, around 30% fell outside our core product range.

Despite this, the client strongly requested a single-source solution to simplify procurement, logistics, and documentation.

Fleyenda provided:

-

Full product integration

-

Unified technical coordination

-

Centralized quality control and documentation

-

One-point communication for the entire valve package

Solution by Fleyenda

Fleyenda worked closely with the client’s engineering and procurement teams to:

-

Review and verify each valve Tag Number

-

Match detailed specifications to operating conditions

-

Optimize materials and sealing selections

-

Coordinate manufacturing and sourcing under a unified technical framework

The result was a fully customized valve package tailored to the pap plant’s operating environment.

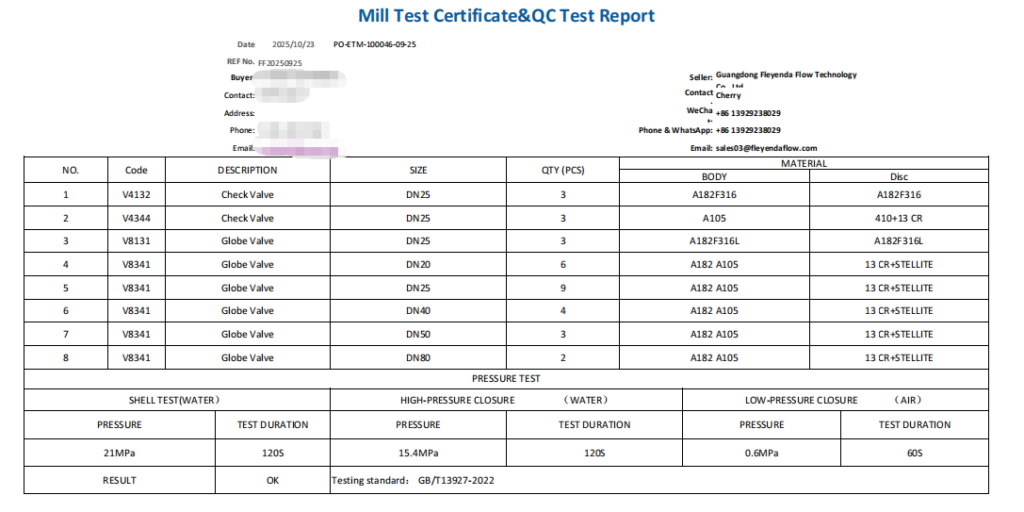

Quality Control & Documentation

To meet the client’s strict engineering standards, Fleyenda provided a complete and traceable documentation package, including:

-

Pressure test reports

-

Material inspection certificates

-

Chemical composition reports

-

Multiple customized material test reports (dozens in total)

-

Complete export and customs clearance documentation

All documents were prepared, reviewed, and delivered according to the project requirements.

(Sensitive client information was anonymized for confidentiality.)

Delivery & On-Site Identification

Before shipment:

-

Each valve was photographed individually

-

Nameplates were marked according to the client’s Tag Number system

-

Every Tag Number corresponded precisely to its valve specification

This approach allowed the client to:

-

Quickly identify each valve upon arrival

-

Install valves accurately at their designated locations

-

Significantly reduce on-site installation errors and dela

-

Project Results

The project concluded with outstanding results:

-

✅ The entire valve package was delivered successfully

-

✅ No after-sales or installation issues were reported

-

✅ Installation efficiency at the site was significantly improved

-

✅ Fleyenda was approved as a designated valve brand for the end user

This project demonstrated Fleyenda’s strength as a reliable valve manufacturer and engineering-oriented solution provider for complex infrastructure applications.